The by far largest amount of mechanical energy introduced to the process is converted to heat during grinding. This heat is then conducted away by chips, cooling lubricant, the grinding wheel and the workpiece. Depending on the process conditions, the amount of heat flow into the workpiece amount to up to 85 % [MARI77, LOWI80, MALK89, TOEN92, BRIN95a, et al.]. The percentile heat flows into the particular components involved in the grinding process are characterised as

• Rw (partial heat flow into the workpiece),

• Rs (partial heat flow into the grinding wheel),

• Rsp (partial heat flow into the chips) and

• Rkss (partial heat flow into the cooling lubricant).

According to Rowe, the following applies overall [ROWE91, ROWE95, ROWE96, ROWE97]:

Rw + Rs + Rsp + Rkss = 1 . (6.51)

From the standpoint of a reliable grinding operation with minimal tool wear and high component quality, an effective heat diversion via cooling lubricant and chips is advisable.

Thermal relations have already been described in numerous experimental and theoretical models. It has been demonstrated that high feed velocities have an advantageous influence on component surface temperatures [KASS69, BRAN78, KOEN79, et al.]. This will be explained further in the following by means of the calculation of heat and temperature balances.

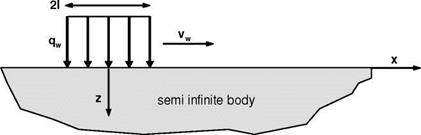

The basis for calculating surface temperatures during grinding was contributed by the approach of CARSLAW and JAEGER [CARS21, JAEG42, CARS59].

|

Fig. 6-28. Model of a heat source in motion adapted from JAEGER [JAEG42] |

By means of equation 6.56, both the maximum temperatures at the component surface as well as in defined depths z beneath the workpiece surface can be calculated. A precise statement of whether, or to what extent, temperatures drop with increasing table feeds can however not yet be made, since the heat flow into the workpiece qw is contingent on the table feed. It results from [ROWE88]:

![]()

|

qw — Rw ‘ qt

![]() with kg : heat conductivity of abrasives

with kg : heat conductivity of abrasives

heat conductivity of material material density

specific heat capacity of material contact radius grit/workpiece

heat distribution factor (percentaged heat flow in cooling lubricant)

heat distribution factor (percentaged heat flow in chips).

The factor Rkss depends via equation 6.62 especially on the contact length lg and the specific grinding energy ec [STEP03]. In the case at hand, a dry grinding process with Rkss — 0 is assumed.

![]() cooling lubricant temperature in the contact zone (corresponds to the evaporation temperature of the cooling lubricant)

cooling lubricant temperature in the contact zone (corresponds to the evaporation temperature of the cooling lubricant)

T0: room temperature (20°C)

hkss : heat transfer factor

The heat transfer factor Rsp (partial heat flow into the chips) is generally calculated with equation 6.63 [STEP03].

The dry grinding processes, that is, without considering cooling lubricant, we obtain with equations 6.51 to 6.63 at constant specific material removal rates Q’w and constant cutting speeds vc the relation in equation 6.64.

0.47

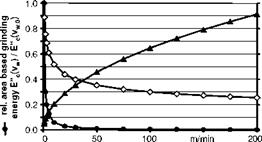

Equation 6.64 shows the favourable influence of increased table feed velocities on component surface temperatures. Neglecting material behaviour, an increase in feed leads directly to a drop in temperature on the component surface (z = 0). Fig. 6-29 shows in addition that the path of surface temperatures largely correlates with the path of area-based grinding energies. Area-based grinding energies can thus be called upon for an initial estimation of the temperature stresses of ground components at varying feed velocities.

Energy-related considerations show the positive influence of high table feed velocities with respect to reduced thermal component stresses during grinding.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![Подпись: Fig. 6-29. Dependence of the relative surface temperature, the relative area-based grinding energy and the contact area-based grinding power on the table speed [ZEPP05]](/img/3149/image210_0.gif)

![]() grinding

grinding

parameters

Q‘w = 30 mm3/mms vc = 125 m/s Qkss = 0 l/min

grinding wheel

ds = 400 mm a = ‘A

reference value

vw0 = 600 mm/min

Further Parameters

The equivalent chip thickness

is an important link between the input, process and resulting parameters. It corresponds to the thickness of a theoretical chip, which is machined from the entrance of a certain cutting edge into the workpiece until its exit. The cutting edge is, for a period of time

engaging with the workpiece. If we add all the engagement times of a cutting edge, we then obtain the equivalent total contact time

which can be used to describe the wear processes of the grinding wheel.