With the help of parameters or characteristics, grinding processes can be generally described independently of the grinding method used. For a methodologically comprehensive comparison of various grinding strategies, various process parameters were generated, which will be described in the following.

Process parameters offer the grinding technician the possibility of comparing various methods and interpreting the output in order to make changes in the variables for the sake of process optimisation. The introduction of numerically con

trolled (NC) machine tools has also inspired increasing interest in parameters. Process control systems require sensors that pick up measurable parameters during the grinding process, e. g. cutting forces or power.

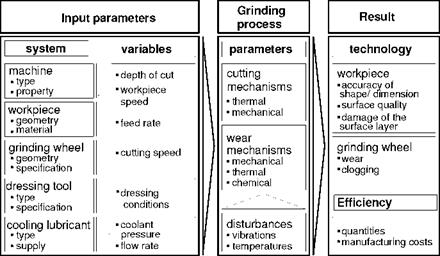

The most important parameters for grinding can be subdivided into input, process and resulting parameters as in Fig. 6-24 [KASS69, MESS83].

Input parameters describe the geometry and kinematics of the grinding process. Among these are those of tool and workpiece form and movement as well as quantities that describe the system, such as cooling lubricant type and supply.

|

Fig. 6-24. The relation between input variables and the result |