One important variable in dressing with rotating dressing tools is the dressing speed ratio qd, defined as the ratio between the peripheral speed of the dressing roller and the peripheral speed of the grinding wheel, as shown in equation 6-9. For down dressing, this value is positive, for up dressing it is positive.

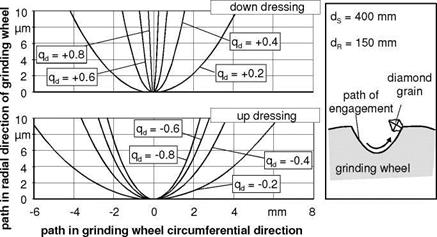

From the superimposition of dressing roller and grinding wheel rotation, the dressing diamonds roughly describe cycloidal paths. In both down and up dress

ing, the length of the engagement path of the dressing diamond grain into the grinding wheel increases with a diminishing dressing speed ratio (Fig. 6-20). The effective angles are flatter at smaller speed ratios qd. The effective paths in down dressing have steeper flanks in principle [STUF96].

|

Fig. 6-20. Effective paths of a diamond grain during dressing [STUF96] |

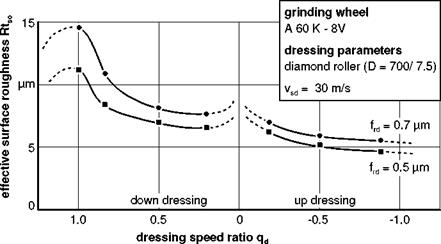

The speed ratio qd thus exerts considerable influence on the effective surface roughness of the grinding wheel. Up dressing produces less grinding wheel roughness, while down dressing with an increasing speed ratio (towards qd = +1) leads to an increasingly coarse grinding wheel topography. This relation is represented in Fig. 6-21.

The initial effective surface roughness Rtso of the grinding wheel shows a characteristic behaviour as a function of the variables speed ratio qd and dressing feed frd [SALJ81, SCHE73, SCHM68].

For a speed ratio qd = 1, crushing, the initial effective surface roughness reaches a maximum. The grinding wheel structure is smashed in the external layers by the high pressure. For a stationary roller (qd = 0) the diamond grains create surface markings that do not overlap in the axial direction. An increase in initial effective surface roughness is the result. These conditions are practically insignificant. If a rough grinding wheel topography is required, one should always use down dressing at ca. qd = 0.8.

Down dressing generally offers the most extensive possibilities for kinematic influence on grinding wheel behaviour (Fig. 6-21). However, it necessitates rigid dressing systems, as the dressing forces are high.

|

Fig. 6-21. Influence of dressing speed ratio and dressing feed on grinding wheel surface roughness [SCHM68] |