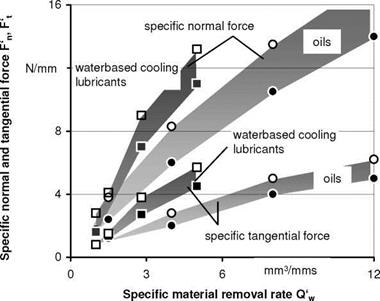

The various cooling lubricants exhibit characteristic properties and also influence the process parameters and its output. Varying friction conditions affect the cutting edge application. In the following, the influence of the cooling lubricant on the cutting forces, heat, surface quality and grinding wheel wear will be demonstrated.

For smaller chip thicknesses, as in finishing, the dependencies shown in Fig. 55 result assuming unchanged grain geometry.

With improved lubrication, the grain normal cutting force increases due to larger cutting depths/deformation. The effective chip thickness/material removal decreases at the same time. As a result, in order to machine a certain volume of material in a predetermined time, the momentary cutting edge number has to go up.

Thus, for small material removal rates, the grain normal force as the sum of all individual grain forces is higher with some oils than in the case with water-miscible cooling lubricants.

On the other hand, the grain tangential force sinks because of lower rake and flank face friction, so that, despite the higher cutting edge number and good lubrication, a smaller tangential component of the total cutting force results, and thus a smaller cutting force ratio.

|

Material |

100Cr6, 62 HRC |

|

Grinding wheel |

EKw 70 Jot 7 Ke |

|

Specific material removal |

V‘w = 250 mm3/mm |

|

Cutting speed |

vc = 45 m/s |

|

Speed ratio |

q = 90 |

|

Spark-out time |

ta = 0 s |

|

Fig. 5-5. Grinding force regions during grinding with oils and water-composite coolants |

As the chip thickness becomes larger (coarse grinding), the cutting edge number changes only slightly percentage-wise with increasing lubrication, so that this influence becomes increasingly insignificant. However, more lubrication leads to a reduction in friction. From decreased friction results a smaller tangential force and thus a smaller total cutting force [VITS85].

The ranges of variation delineated in Fig. 5-5 make it clear that the composition of the cutting oil or water-based cooling lubricant exerts an influence on the cutting forces. Generally, the results respectively the differences between various

cooling lubricants, depend to a large extent on the respective application at hand, for example, on the material to be machined.

|

Material |

100 Cr 6, 62 HRC |

|

Grinding wheel |

EKw 70 Jot 7 Ke |

|

Specific material removal |

V‘w = 250 mm3/ mm |

|

Cuting speed |

vc = 45 m/ s |

|

Speed ratio |

q = 90 |

|

Spark-out time |

ta = 0 s |

|

emulsion with mineral oil concentration 3 — 8 % |

Also of great practical importance is the question of which type of cooling lubricant causes more thermal stress on the workpiece, the undesirable results of which are, among other things, structural changes and tensile residual stress (danger of cracking) in the workpiece external zone. It is however not possible to make conclusive statements about this, since the effect of different cooling lubricants on external zone damage is contingent on the respective application.

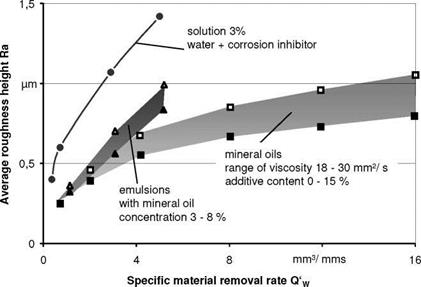

With higher material removal rates, oils are more advantageous than emulsions with respect to grinding wheel wear as well as the resultant surface quality (Figs.

5- 6 and 5-7). On the other hand, water-based cooling lubricants are to be recommended for precision grinding, because they provide better dimensional and formal accuracy as well as less danger of thermal workpiece damage due to their lower normal forces and their ability to remove heat more quickly. Moreover, using oil in precision grinding and the chip thicknesses associated with it can lead to insufficient chip formation.

|

Material |

100 Cr 6, 62 HRC |

|

Grinding wheel |

Ekw 70 Jot 7 Ke |

|

Specific material removal |

V‘w = 250 mm3/ mm |

|

Cutting speed |

vc = 45 m/ s |

|

Speed ratio |

q = 90 |

|

Spark-out time |

ta = 0 s |

|

Fig. 5-7. Surface quality against type of coolant |