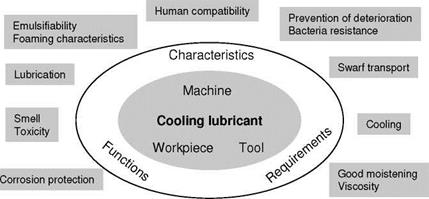

The properties of cooling lubricants and the demands placed on them are manifold (Fig. 5-2). Not only technical performance, but also economical, ecological as well as safety and health concerns play a role.

One of the most important physical properties of cooling lubricants is viscosity. This describes internal resistance of a fluid to deformation. Viscosity has a direct influence on the load capacity of the lubrication film that forms between the tool and the workpiece, but it also influences other important properties of the cooling lubricant. Low viscosity increases the cooling and rinsing effect and also brings about a decrease in drag-out losses, since low-viscosity cooling lubricants are easier to separate from chips and workpieces. Low viscosity also facilitates filter behaviour and air separation characteristics. On the other hand, low viscosity generally also entails increased proneness to oil vapour and aerosol formation (oil mist), a low flashpoint as well as an increase in skin irritations due to degreasing [BAUM00, REHB01, SCHU03].

|

|

|

Compatibility with materials |

Cleaning effect |

|

|

Washability |

|

Recycling ability Fig. 5-2. Requirements of coolants [N. N.93] |

|

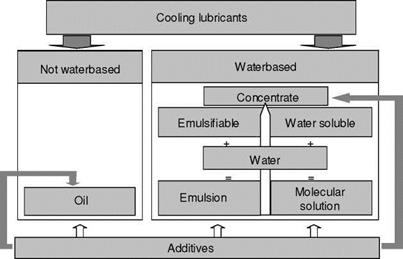

Fig. 5-3. Classification of coolants |