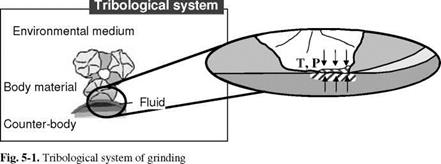

In the grinding process, all the components involved — the grain material (including the bond) as the body, the workpiece material as the counter-body, cooling lubricant as the intermediate substance and air as the environmental medium — form a tribological system (Fig. 5-1). Thus, in order to optimise the cooling/lubrication system, all components involved as well as the collective dominating tribological load (movement, pressure, temperature) must be taken into consideration.

|

|

Aside from cooling the process, the cooling lubricant also has the task of influencing the friction conditions between the grain material and the workpiece material advantageously and thus of decreasing grinding wheel wear in general. The physical and chemical properties of cooling lubricants determine their effectiveness in tribological contact. By reacting with the cooling lubricant in the contact zone, intermediate layers can emerge that can assist in separating the surfaces and reducing friction. The cooling lubricant thus has an essential influence on the friction condition between the body and its counter body and thus also affects the chip formation process and grinding wheel wear.