Case-hardened steels include unalloyed construction steels, grade and special steels as well as alloyed special steels. Common to all of these is a relatively low carbon content (C < 0.2 %). Typical carbon contents and alloying components of case-hardened steels are represented in table 4-2.

|

Element |

C |

Si |

Mn |

P |

S |

|

Amount in % |

0.07 — 0.2 |

< 0.4 |

0.3 — 1.4 |

< 0.045 |

0.02 — 0.045 |

|

Table 4-2. Composition of case-hardened steels |

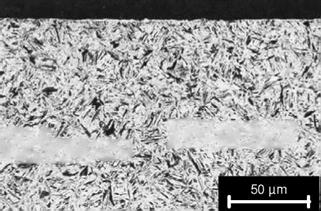

Machining with geometrically undefined cutting edges takes place in a case — hardened condition. In case-hardening, the surface layer of the workpiece is carburised to 0.6 — 0.9 % carbon. The hardening process leads to a martensitic structure in the external layer (Fig. 4-6). Beyond this, portions of residual austenite and/or cementite are possible at carbon contents over 0.7 %. In this case, there are hardness values of up to 60 HRC at high tensile strength and low toughness.

Case-hardened steels are predominately utilised in the manufacture of high — wear and non-uniformly stressed parts like gear-wheels, gear shafts, joints, connectors etc. Examples of case-hardened steels are Ck15, 16MnCr5, 20MoCr4 and 18CrNi8 [N. N.98].

Fig. 4-6. Microsection of case-hardened steel 16MnCr5