The most dramatic differences in performance occur between the grinding behavior of molten and sintered corundum. The introduction of sintered corundum led to tremendous tool life enhancements.

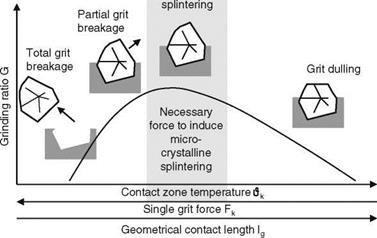

The higher wear resistance and larger material removal rates of micro crystalline corundum compared to molten corundum results not only from the higher toughness of the abrasive material but also from the specific wear behavior [MULL01, p. 122 f., UHLM97]. Sintered corundum types consist of small crystals, which wear by breakout [LUDE94, p. 74]. The longer crystal boundaries that have to be broken lead to higher grit toughness. The specific wear mechanisms are based on micro-crystalline fracture, so that only small particles break out of the sol-gel corundum grits and establish a self-sharpening effect [MULL01, p. 122 f., UHLM97]. However, this micro-crystalline fracture only appears above a certain load. Below this minimum load, corundum grits wear mainly by surface flattening (Fig. 2.9) [MULL01, p. 122 f., UHLM97]. The right process design, e. g. working with high material removal rates, is crucial for an efficient, sustainable process.

|

Micro crystalline

Fig. 2.9 Wear behavior of sol-gel corundum depending on the single grit load, after [UHLM97] |

Another mechanism is the presence of cavities in the abrasives [LUDE94, p. 76]. They act like hindrances and split cracks in smaller micro cracks. Furthermore, comparatively long crystals with high tear strength (whiskers) in a tough matrix can increase grit toughness [LUDE94, p. 76]. The crystals are pulled out off the matrix during crack propagation. This leads to a zipper effect, which absorbs the crack energy.

The high aspect ratio of extruded sol-gel corundum results in a low packing density of these grains of only 30 % by volume [MARI07, p. 113]. So grinding tools of very high porosity can be manufactured for high performance processes where pores get clogged easily. Vitrified grinding wheels with this grit type are on the market with an interlinked porosity of 65-70 % and they prove to be well suited for high efficiency grinding with low process heat [MARI07, p. 113, WEBS04].