|

|

The strength of steel can also be increased by hardening and subsequent tempering. In tempering a material, the martensite formed during hardening is specifically brought again to partial disintegration by re-heating, thereby relaxing the crystal lattice. At low annealing temperatures, carbon precipitates in a finely distributed fashion, while at higher temperatures coarser cementite grains develop [SCHU78].

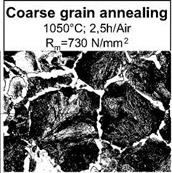

Several possibilities for a targeted influence on structure by various heat treatments are show in Fig. 4-5 using the heat-treated steel Ck45 as an example. The allocation of the partial images to the heat treatments is as follows:

1. Coarse-grain annealing

Structural components: Coarse-grained pearlite with lamellar cementite, a ferrite network between the grains (white in the microsection).

2. Normalising

Structural components: Pearlite with lamellar cementite, ferrite. These are the same components as in coarse-grain annealing, but the structure is finer-grained and more homogeneous.

3. Heat treatment

Structure: Tempered martensite.

4. Annealing

Structural components: Ferrite (white in the microsection) with globularly shaped cementite.