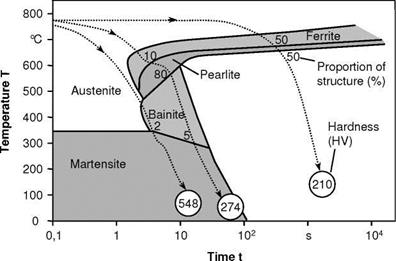

A further type of material heat treatment is hardening (H) and austempering. During steel hardening, first the carbon is dissolved in the austenitic zone. The carbon precipitation that takes place at normal cooling speeds is then stifled by a high cooling speed. Thus, at supercritical cooling speeds, after falling short of the Ms — temperature (Ms = martensite starting), instead of ferrite, with its body-centred cubic a-latticework, a latticework is formed that is deformed and stiffened by carbon and is still tetragonal, i. e. tetragonal martensite. It can be recognised on the micrograph as a needle-shaped structure and is characterised by a high level of hardness and tensile strength. Nevertheless, it exhibits almost no fracture elongation [N. N.98a, SCHU78]. At cooling speeds lower than the critical cooling speed, the conversion processes proceed in the intermediate stage and in the pearlite stage [N. N.54]. Conversion in the intermediate stage is basically characterised by that fact that only the carbon can diffuse. Fig. 4-4 shows these processes during a constant cooling. These grain structures do not exhibit good machining behaviour, since the tools used are subject to increased abrasive wear. Chip formation, however, can be considered good.

|

Fig. 4-4. Continuous time-temperature transformation representation for Ck45 |