Materially speaking, the machinability of steels is determined by its structure and mechanical properties (hardness, tensile strength). Of primary importance for the composition and thus for the mechanical properties as well are:

• carbon content (C-content),

• alloying elements and

• heat treatment.

The percentile amounts of carbon or other alloying elements given in this chapter signify their percentage by weight.

4.2.1 Material Properties as a Function of Carbon Content

Using non-alloy grade steels (carbon steels) and minimally alloyed steels (sum of alloying elements < 5 %), the influence of the carbon content on machinability with be clarified in the following. Carbon content is responsible for the structural configuration of these steels and thus for their hardness and tensile strength as well.

The basic structural components of non-heat-treated steels are:

• ferrite (a-iron),

• cementite (Fe3C) and

• pearlite.

The amounts of these structural components, the particular properties of which (table 4-1) determine the machinability of the steel material at hand, vary depending on the C-content.

|

Table 4-1. Mechanical properties of the basic structural components of the iron-carbon system

|

Ferrite

The body-centred cubic a-mixed crystals are designated as ferrite. Ferrite is characterised by relatively low strength and hardness while at the same time exhibiting high deformability.

Cementite

Cementite is the metallographic name for iron carbide (Fe3C). The structural component cementite is hard and brittle and can only be machined with difficulty. Cementite can appear freely are dissolved in pearlite depending on the carbon content of the steel.

Pearlite

Pearlite is a eutectoid mixture of ferrite and cementite. For the most part, lamellar, linear cementite appears in pearlite. After to a corresponding heat treatment (annealing) however, globular (spheroid) cementite can also be formed.

Austenite

Face-centred cubic (fcc) у-iron is called austenite. In low-alloyed carbon steels, austenite at room temperature is generally not stable and disintegrates beneath the Ac1-temperature into ferrite and cementite.

In higher-alloyed steels, elements of the VIII group of the periodic table and manganese stabilise austenite to lower temperatures. In extreme cases, a composition of pure austenite can be produced at room temperature by suspending austenite decay [N. N.98a].

Martensite

Martensite is a structural form with a tetragonal tensed latticework that is formed by a rapid cooling of austenite. A more detailed description is found in chapter 4.2.3.

|

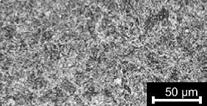

Carbon steels with a carbon content of C < 0.8 % are called subeutectoid carbon steels. The essential structural components of non-alloyed subeutectoid carbon steels is shown in Fig. 4-2.

Tetragonal tensed lattice Very high hardness (700 -900 HV10)

High tensile strength Almost no fracture strain

Fig. 4-2. Structural Components of Carbon Steels

The machinability of steels with a C-content < 0.25 % is essentially characterised by the properties of free ferrites.

The amount of pearlite increases at higher carbon contents (0.25 % < C < 0.4 %). In this way, the special machining properties of pearlite become more influential on the machinability of the material.

A further increase in carbon content (0.4 % < C < 0.8 %) causes a further reduction in ferrite content in favour of pearlite, until at 0.8 % C only pearlite remains. The consequences for machinability comply with the tendencies already identified for steels with low C-contents.

For supereutectoid carbon steels (C > 0.8 %) pearlite and cementite are also formed when slowly cooled in air. As opposed to subeutectoid C-steels however, no free ferrite appears as a ferrite net. Pearlite formation initiates directly from the austenite grain boundaries. At C-contents clearly over 0.8 %, cementite is precipitated at the grain boundaries. The cementite, now also freely available, forms shells around the austenite/pearlite grains [SCHU78].