4.1 The Concept of “Machinability’’ in the Grinding Process

Machinability is understood as a property of a material that allows for chip removal under given conditions. It thus describes the behaviour of a material during chip forming.

The machinability of a material must always be considered in conjunction with the machining method, the tool and the machining parameters.

In comparison to machining with geometrically defined cutting edges, grinding manifests clear procedural differences that effect the machinability of the materials. During grinding, machining is achieved by means of a number of individual grit engagements. Together with the strongly negative tool orthogonal rake angle of the grit, there is, in contrast with geometrically defined chip removal, an increased amount of friction and deformation work, from which results a higher conversion of energy in the process. This in turn can lead to heavier thermal stress on the surface layer. Small depths of cut result from the geometrical process characteristics of grinding and the high cutting speeds. Thus, the grain size of the workpiece material as well as the size of inclusions (e. g. carbide) play a role with respect to machinability. This problem should certainly be considered in process construction as a scaling effect.

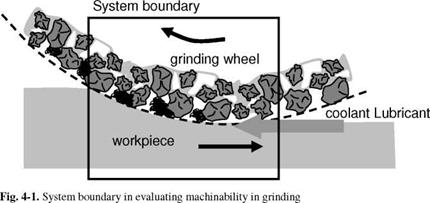

For evaluating the grindability of various materials, the system boundary of the contact zone must be considered (Fig. 4-1). A multitude of individual grit contacts are made in the grinding process. Thus, besides the particular abrasive grains, the space between the grain and therefore the entire abrasive coating bond must be taken into account.

The machinability of a material is determined by all the elements of the grinding system. All components, i. e. the grinding wheel (specification and preparation), process parameters and cooling lubricants, have to be adjusted for the respective material and the machining goals (component requirements, productivity, quality).

The workpiece surface layer created (thermal and mechanical influences) as well as chip formation can be called upon as criteria for the evaluation of ma — chinability. Grinding forces, workpiece roughness, possible clogging of the grinding wheel and macroscopic and microscopic grinding wheel wear can all occur during chip formation. Chip formation and surface layer properties thus limit potential material removal rates and workpiece roughness. Concrete suggestions for

the abrasive machining of a particular material can only be made in the context of the grinding method used, the component requirements and other marginal conditions.

|

|