The determination of the amount of wear of the grits and the bond of grinding wheels is very difficult. Approaches to this are based on the ascertainment of the

force required to detach a grit from the bond. With this method, bond strength becomes quantifiable.

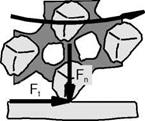

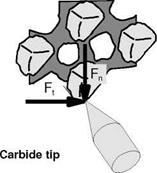

For the execution of the grit break-out experiment, a sharpened carbide tip is directed towards a single grit by means of a swivelling device, under the effective angle of cutting force arising during grinding, and moved constantly toward the grit with a multiphase motor (Fig. 3-21).

By means of corresponding sensors, the force acting on the break-out tips and the corresponding path is recorded with a Piezo force sensors and an inductive path sensor. With the use of a force-path signal, an assessment of the fracture phenomena grit break-out, grit fracture or bond fracture caused by the break-out tip is undertaken (fig 3.22).

The grit break-out approach may still be under development, but this characterisation method is the only one which makes it possible to test and to characterise both conventional and superabrasive grinding wheels. In contrast, hardness testing methods like the grindo-sonic or the Zeiss-Mackensen methods can only be utilised for solid body grinding wheels.

|

|

Real grinding process: Grit breakout test:

Fig. 3-21. Alignment of the carbide tip for the execution of the grit break-out experiment

|