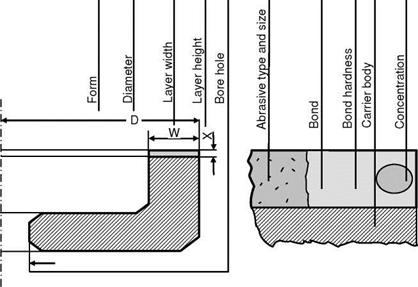

There is still no binding norm for the designation of grinding wheels containing diamond or boron nitride. The parameters can however be compiled from the manufacturer specifications and from the FEPA standard [N. N.10]. In accordance with these, the identification of a diamond or cBN grinding wheel is composed of a designation of its shape and dimensions as well as the identification of its actual grinding wheel layer (Fig. 3-16). The latter identification specifies grit type and granulation, the bond, bond strength, body and grit concentration.

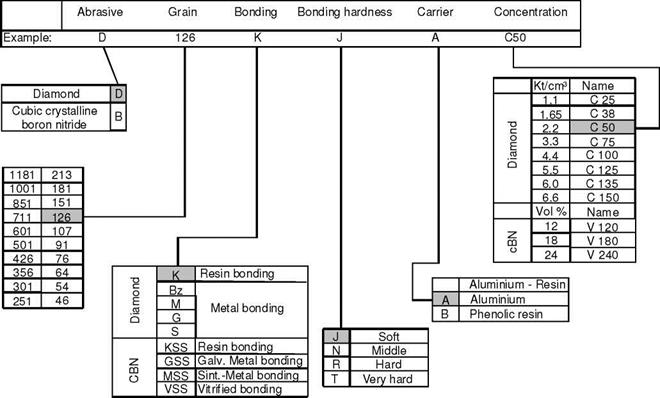

Fig. 3-17 shows a further subdivision in the designation of superabrasive grinding wheels. According to this, diamond D and cBN B stand for both available grit types. The granulation number following the abrasive designation indicates the mesh width of the corresponding test sifts. In contrast to conventional abrasives, it specifies the average grit diameter in |im. We can see from the subsequent combination of letters and numbers which bond type is used in the grinding component that is to be identified. Extensive freedoms are still available to the manufacturer in designating particular bonds. Bond strength is differentiated for cBN and diamond grinding wheels by means of letters.

|

GA 2 — 125 — 15 — 2 — 20 — D 126 K-plus 888 J A C 50

Fig. 3-16. Structure of the designation of diamond grinding wheels [N. N.10] |

After the body designation follow specifications concerning grit concentration. Leading diamond tool manufacturers have agreed on a concentration identification, the basis of which is defined as follows: The concentration number 100 corresponds to a weight concentration of 4.4 carat/cm3. This is equivalent to a volumetric diamond percentage of 25 % of the total coating volume, taking as a basis a diamond density of 3.52 g/cm3 (1 carat = 0.2 g). Usual concentrations are

• 25 = 1.1 ct/cm3,

• 38 = 1.65 ct/cm3,

• 50 = 2.2 ct/cm3,

• 75 = 3.3 ct/cm3,

• 100 = 4.4 ct/cm3,

• 125 = 5.5 ct/cm3,

• 135 = 6.0 ct/cm3,

• 150 = 6.6 ct/cm3.

For cBN grinding wheels, concentration specifications usually correspond to ten times the value of the volumetric grit percentage of the total coating volume [N. N.10].