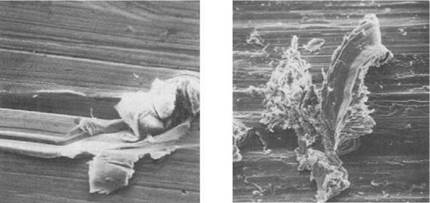

Knowledge of the basic principles of a machining method is an essential prerequisite for the full realisation of its potential. Yet research into the essential features of material removal with geometrically undefined cutting edges is beset with great difficulties. The determination of the cutting edges used in the procedure is hampered by the extremely complex microstructure of the tools. Because of the large number of grain points acting on the component part, material removal is made up of the sum of many different cutting edge engagements that remove the individual chips from the material surface (Fig. 2-1).

cutting direction

|

|

25 pm 10 pm

Material: Ck15N Material: Ck45N

Fig. 2-1. Images of chip roots taken with a scanning electron microscope [LORT75]

Grinding is used primarily as a precision machining method in which chip formation proceeds within the realm of a few micrometers and to a large extent eludes direct observation. However, due to theoretical considerations and with the help of investigations into the physical and chemical processes, we can make assertions about this process as well. Such findings are necessary for basic understanding and are of invaluable help in the optimal design of machining processes.