8.1.1 Loss of Accuracy and Productivity

Vibrations can cause serious problems in grinding processes leading to loss of machining accuracy and loss of productivity. Of the various types of vibration, chatter vibration is one of the most crucial ones because it reduces form accuracy as well as increasing surface roughness of the ground parts. Form accuracy and low surface roughness are two of the main targets to be attained by grinding. In addition, productivity is lost because material removal rate has to be reduced as a way of suppressing chatter. A great deal of research has been conducted that is aimed at achieving a clear understanding of the mechanism of chatter vibration and consequently at developing practical suppression methods.

8.1.2 A Need for Chatter Suppression

The ultimate aim of research on grinding chatter is to develop practical methods for suppressing chatter vibrations while maintaining high productivity. While there have been some proposals from research laboratories to meet this requirement, few have been successfully applied in industry. Thanks to significant developments in sensing and control technologies available today, it seems that the necessary tools for developing methods of suppressing chatter vibrations are being provided.

8.2 FORCED AND REGENERATIVE VIBRATIONS

8.2.1 Introduction

|

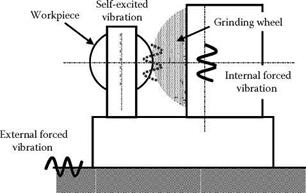

There are basically two types of vibration in grinding processes: forced vibrations and self-excited vibrations (Figure 8.1).