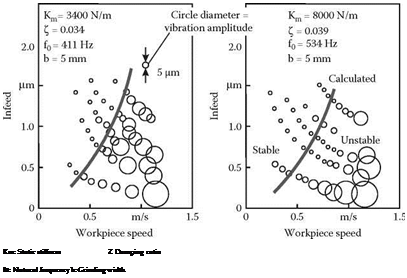

The development of regenerative chatter amplitude in cylindrical grinding is schematically illustrated in Figure 8.2. When the workpiece velocity is extremely high, of the order of some 10 m/min, or the chatter frequency is low, vibration with large amplitude can be observed at the beginning of grinding even if a newly dressed grinding wheel is used. In addition, significant chatter marks can be observed with the naked eye on the workpiece surface suggesting that the work-regenerative effect is the main reason for this vibration.

The occurrence of this chatter is significantly influenced by the combination of set-up parameters as shown in Figure 8.3 [Sugihara, Inasaki, and Yonetsu 1980a]. To the contrary, when the workpiece velocity is decreased to the order of some m/min, or chatter frequency is high, vibration cannot be detected at the beginning of grinding. However, the amplitude increases gradually as the grinding time advances. In this case, the chatter marks are not easily seen with the naked eye on the ground surface. However, the surface roughness perpendicular to the grinding direction deteriorates a lot. The

.

rate of amplitude increase is affected by the combination of set-up parameters and the type of grinding wheel used. The chatter frequency, which is closely related to the natural frequency of the mechanical system, and the workpiece velocity have a dominant effect on the occurrence of two different types of regenerative chatter vibration. Furthermore, it can be generally said that grinding processes are, in most cases, unstable in terms of the grinding wheel regenerative chatter [Inasaki et al. 1974]. In other words, the speed of the vibration development is a matter of concern with respect to this type of chatter.

|

Other important factors to be taken into account in terms of grinding chatter are the elastic deformation of the grinding wheel [Brown, Saito, and Shaw 1971, Inasaki 1975] and the geometrical interference between the grinding wheel and the workpiece [Rowe and Barash 1964]. The influence of the former factor on the stability will be discussed in Section 8.4.