7.5.1 Introduction

The rules for dressing vitrified CBN wheels are similar in many ways to those described for conventional wheels. The same concepts of crush ratio, traverse rates, effective contact width, and depth of cut apply. The changes that must be made to the dressing conditions relate to the greater hardness, toughness, and cost of the abrasive, and the greater hardness of the bond.

7.5.2 Dressing Depth

First and foremost, the depth of cut per pass with CBN is greatly reduced. This is, in large part, an economic requirement and the effect of this is to reduce the maximum surface roughness due to geometric effect from the truer. That, combined with the harder wheel grade, makes a higher crush ratio necessary and a more aggressive truer design to compensate. Whereas most conventional wheel applications run with a negative crush ratio, CBN is generally dressed with a crush ratio of +0.4 to +0.8. The only exceptions to these are where dressing is expressly required to lower finish to a minimal value, or because of a lack of dresser spindle motor torque.

|

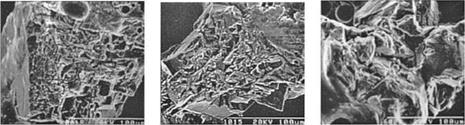

Micro-fracture Medium-fracture Macro-fracture FIGURE 7.21 Fracture modes of 80# GE type 1 abrasive. (From Ishikawa and Kumar 1991. With permission.) |