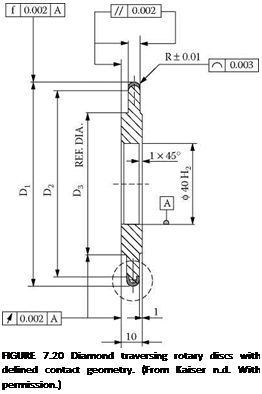

Traverse rates should be calculated from actual geometry of the disc. For discs of a given tip radius, r, and depth of dress, ad, simple geometry gives the effective contact width as bd = 2[(2r — ad)ad]J. The same rules for overlap factor, Ud, as a function of bd apply as for stationary tools. Dress infeed amounts should be limited to the range of 5 to 20 pm. Truing forces are low and, for the small — radii discs, comparable to single-point dressing. Consequently, the dresser spindle motors require relatively modest power (<0.2 KW) and stiffness requirements resulting in compact units that can be readily fitted or retrofitted to the grinder.

7.4.3 Synthetic Diamond Discs

Synthetic diamond discs are expensive but the initial outlay can be compensated for by the fact that if wear is properly monitored before becoming catastrophic, the discs can be relapped up to 40 times [Dr. Kaiser n. d.].

7.4.4 Sintered and Impregnated Rolls

Less expensive are sintered, impregnated, or “infiltrated” rolls, which consist of a molded layer of diamond abrasive grains. These will contain a random distribution of diamonds. The rolls tend to be of a relatively large radius <1/8 in., which may be relapped two to three times, or a flat profile with a consumable layer of 2 to 5 mm.

7.4.5 Direct-Plated Diamond Rolls

Another low-cost, throw-away alternative for some applications is direct-plated diamond with similar profiles to sintered rolls.

7.4.6 Cup-Shaped Tools

|

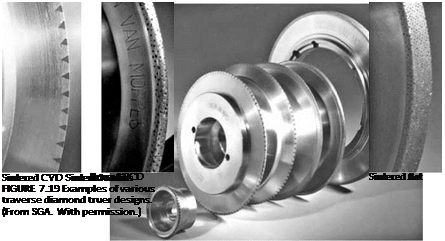

Cup shapes, as well as discs, are used as illustrated by the example in Figure 7.19. A cup-shaped tool is used tilted to the wheel face at an angle usually defined more by space availability for the

|

|

|

motor than by the optimum dress geometry. Cups are either used where space is confined, such as in internal grinding, or where an outer diameter and face must be dressed. The other situation for their use is with low-torque dresser motors (see later). In the case of sintered cups, the tilt angle is prelapped in the face of the cup to avoid break-in issues.