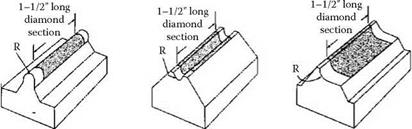

In addition to the stationary tools for traverse dressing, full forms can be dressed simultaneously using form blocks. These are blocks that have a layer of diamond either sintered or directly plated and molded to the form required in the wheel. They are used especially in surface grinding where the block is set on the table at the same height as the finished ground height. The reciprocating

table 7.4

Grit Tool Recommendations for Conventional Wheels

|

Diamond Grit Size |

Abrasive Grit size |

Type |

|

18/20 |

46# |

round |

|

20/25 |

54# |

round |

|

20/30 |

60# |

block |

|

20/30 |

80# |

block |

|

30/40 |

100# |

block |

|

40/50 |

120# |

block |

|

bd |

L |

Application |

|

v |

N/A |

small toolroom |

|

3/8" |

N/A |

medium toolroom |

|

V2" |

<20" ф x <10" wide |

|

|

V4" |

%" |

>20" ф x <10" wide |

|

3/8" |

V2" |

<20" ф x >10" wide |

|

3/8" |

%" |

>20" ф x >10" wide |

|

|

|

|

|

|

|

stroke length is adjusted so that it dresses the wheel before finish grind. The blocks are either molded to the full form required or supplied as standard shapes for flexibility in toolroom applications. Dimensional form accuracies can be held to ±5 pm; minimum radius capability is 75 pm (Figure 7.14).