Prior to the introduction of synthetic needles natural long stones were used. These have trade names such as the Fliesen tool from Winter (Saint-Gobain Abrasives). Some tools of this style have multiple layers of diamonds to maximize tool life, but care needs to be taken in their design to avoid changes in dress behavior when transitioning from one layer to another.

|

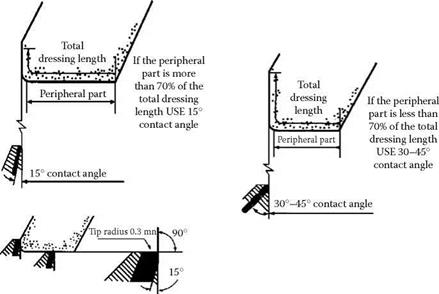

Blade tools have double the truing forces of single-point diamonds (50 to 150 N depending on wheel grade and grit size) but can handle depths of cut up to 50 pm for roughing of regular abrasive. For ceramic-type abrasives, the maximum dress depth is 25 to 20 pm. bd is typically 0.75 to 1.0 mm. As with single points, the tools should be biased by up to 30° in the direction of traverse (Figure 7.10 and Figure 7.11).

|

FIGURE 7.11 Examples of blade tools with natural long stones.