7.2.1 Nomenclature

The terminology for the various parameters involved in dressing is as follows:

ad = dressing depth of cut (or dress infeed amount) per pass bd = effective contact width of the dressing tool ns = grinding wheel rpm

fd = axial tool traverse across grinding wheel surface, feed/rev Ud = dressing overlap ratio vfd = axial tool traverse feed velocity

|

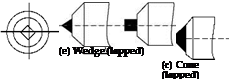

(a) Rough diamond (b) Pyramid (lapped)

(d) Flat (lapped)

FIGURE 7.1 Standard single-point diamond shape.

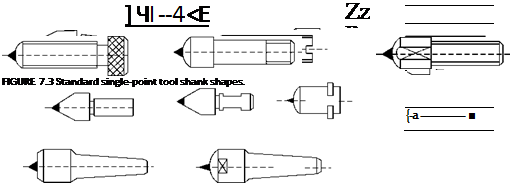

7.2.2 Single-Point Diamonds

The simplest tool is the single-point diamond. Typical designs of the diamond are shown in Figure 7.1, Figure 7.2, and Figure 7.3. The majority of tools are A-shaped with the corner of rough unlapped diamonds. In general, these corners are well-enough defined for repeatable dress action for flat wheel forms. The diamond is buried in a metal matrix with about one third of the diamond exposed. High-quality diamonds tend to have up to four usable points and the tools can be returned to the toolmaker for resetting. Although the intitial cost is higher, this is usually the most cost — effective choice unless tools are being abused. In this case, much lower quality throw-away tools are recommended. The diamond weight can vary from a standard V2 ct up to 2 ct for aggressive or heavy dressing.

Diamond Size

|

General recommendations for diamond size are based on wheel size as in Table 7.1.

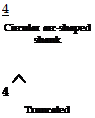

Shoulders chamfered

and wedged

FIGURE 7.2 Standard single-point diamond top-end shapes of tool shanks.

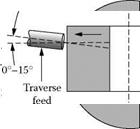

7.2.4 Scaif Angle

The diamond is mounted in a holder and held at a scaif angle against the wheel rotation and with the traverse motion as illustrated in Figure 7.4. The single point cuts a thread across the face of the wheel fracturing or dislodging grains and bond leaving a fresh topography on the wheel surface (Figure 7.5).

7.2.5 Cooling

Copious coolant should be applied as the diamond is heat sensitive and the tool holder should have its own coolant nozzle. The coolant supply must be turned on before commencing a dressing pass. If the coolant is turned on during a pass, the diamond may be damaged by severe thermal shock.

Single-Point Diamond Size Recommendations for Single-Point Tools Based on Wheel Diameter

![]()

|

Up to 3" 3" to 7"

8"to 10" 11"to 14" 15"to 20" Over 20"

|

|

FIGURE 7.4 Dressing configuration using single-point diamonds. (From Rappold 2002. With permission.)