6.10.1 Introduction

Phenolic bonds represent the largest market segment for conventional grinding wheels after vitrified bonds, and dominate the rough-grinding sector of the industry for snagging and cutoff applications. The bonds consist of thermosetting resins and plasticizers, which are cured around 150 to 200°C. The bond type was originally known as “Bakelite” and for this reason still retains the letter “B” in most wheel specifications. Grade or hardness is controlled to some extent by the plasticizer and use of fillers.

6.10.2 Controlled Force Systems

Unlike vitrified wheels, most resin wheels are used under controlled pressure, that is, controlled force rather than fixed infeed systems, and very often at high speed.

Standard Pressure Ranges for Conventional Resin Bond Cutoff Wheels

Operation

Operation

Portable grinder

Floorstand

Swing frame

Remote control machine

Pressure-controlled grinding [Coes 1971]

6.10.3 Abrasive Size

Abrasive size is usually used to control recommended grade. Finer grit wheels remove material faster for a given pressure, but wear faster, and are used to avoid the excessive porosity that would be required in a coarse wheel to get cutting action. Porosity reduces burst speed and allows grits to be easily torn out. With available pressures, coarser grit sizes can be used (Table 6.6). Glass fibers are also added to reinforce cutoff wheels for higher burst strength.

6.10.4 Benefits of Resilience

Resin bonds are also used for precision applications where its resilience provides benefits of withstanding interrupted cuts and better corner retention. One such area is flute grinding of steel drills where the wheel must maintain a sharp corner and resist significant side forces. There have been enormous improvements in life and removal rates over the last 10 years with the introduction of SG and most recently TG abrasives. Some are capable of grinding at Q’ > 100 mm3/mm/s while still producing several drills between dresses. This is one example where advances in conventional engineered abrasives are competing very successfully with emerging CBN technologies.

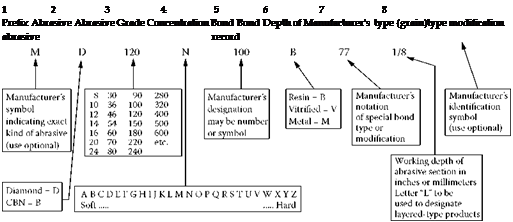

ANSI Standard Marking Systems for Superabrasive Wheels

Diamond and CBN Marking System Chart

|

Sequence