With the abrasive volume defined, the remaining volume is shared between the bond and porosity. The bond bridges can obviously be strengthened by increasing the amount of bond to make them thicker. The greater the amount of bond present, the lower the porosity and the harder the wheel will act. The actual definition of Grade will again vary from supplier to supplier. For some it is simply a direct correlation to porosity; for others it is a more-complicated combination of porosity

|

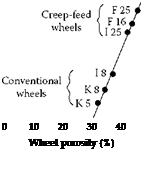

FIGURE 6.5 Porosity for various Norton grade/stracture combinations. (Engineer et al. 1992. With permission.)

percent, P, and structure number, S. Malkin [1989] gives one supplier’s system where the grade letter is correlated according to

Grade ~ 43.75 — 0.75P + 0.5S

This definition is designed to make grinding performance characteristics relate to grade (e. g., burn, dressing forces, power, etc.) so that grinding performance changes more predictably from one grade letter to the next.

The interplay can also be seen in Figure 6.5 which gives the porosity level for various Norton grade letter/structure number combinations.

More formally, vitrified bond systems are described by ternary phase diagrams that map the allowed bond/grain/porosity combinations as shown in the example in Figure 6.6 [DiCorletto 2001].