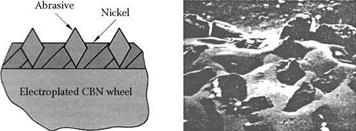

The hardness, or more accurately the wear resistance of the nickel, is controlled by changes to the bath chemistry. Nitride coating, similar to coatings used on cutting tools, has been reported to further improve the wear resistance of the nickel, but data have been mixed indicating that performance parameters are not yet understood [Julien 1994, Bush 1993]. Solid lubricant coatings of the wheel surface have also been reported to increase life.

|

TABLE 6.1 Direct Plating Grit Size Allowances

|

6.3.3 Grit Size and Form Accuracy

The size of the grit must be allowed for when machining the required form in the blank. This will be different to the nominal grit size and dependent on the aspect ratio of the particular grit type. For example, Table 6.1 gives standard values for GE 500 abrasive with an aspect ratio of 1.4.

6.3.4 Wheel Wear Effects in Grinding

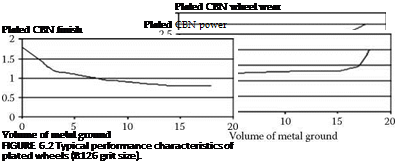

One major attraction of plated wheels is the fact that they do not require dressing and, therefore, eliminate the need for an expensive diamond form-roll and dressing system. However, plated wheels present challenges to the end user due to the effects of wheel wear. Figure 6.2 illustrates changes in grinding power, workpiece roughness, and wheel wear with time for a typical precision-plated wheel when CBN grinding aerospace alloys. Initially, the surface roughness is high as only the very tips of the grits are cutting. The power then rises rapidly together with an associated rapid rate of wheel wear and a drop in roughness. The process tends to stabilize, with wear flat formation

|

|

FIGURE 6.1 Schematic of an electroplated cubic boron nitride wheel section and the appearance of the actual surface of such a wheel.

|

being balanced by fracture, unless the grinding conditions are too aggressive. This leads to a much more protracted period of time when the rates of change of all three variables are reduced by up to a factor 10. Failure occurs when power levels finally become so high that burn occurs, or the plating and grain are stripped from the core. This latter effect is particularly concerning because in most cases it cannot yet be detected in advance or predicted easily except by empirical data from production life values from several wheels.