The resultant abrasive is called brown alumina and contains typically 3% TiO2. It has a Knoop hardness of 2,090 and a medium friability. Increasing the TiO2 content increases the toughness but reduces hardness. Although termed brown, the high temperature furnacing in air required in subsequent vitrified wheel manufacture turns the brown alumina grains a gray-blue color due to further oxidation of the TiO2.

5.4.2 White Alumina

Electrofused alumina is also made using low-soda Bayer Process alumina that is >99% pure. The resulting grain is one of the hardest, but most friable, of the alumina abrasive family providing a cool-cutting action especially suitable for precision grinding in vitrified bonds. Also, its low sodium content deters wheel breakdown from coolant attack when used in resin bonds.

White alumina is the most popular grade for micron-sized abrasives in part because the crushing process concentrates impurities in the fines when processing other alumina grades. To produce micron sizes, the alumina is further ball-milled or vibro-milled after crushing and then traditionally separated into sizes using an elutriation process. This is achieved by passing a slurry of the abrasive and water through a series of vertical columns. The width of the columns is adjusted to produce a progressively slower vertical flow velocity from column to column. Heavier abrasive settles out in the faster flowing columns while the lighter particles are carried over to the next. The process is effective down to about 5 pm and is also used for micron-sizing SiC. More recently, air classification has also been adopted.

|

FIGURE 5.2 Pouring of molten alumina. (From Wellborn 1994. With permission.) |

|

Silicon carbide |

White alumina

Alumina-Zirconia

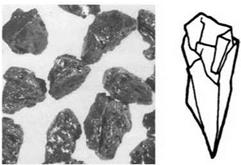

FIGURE 5.3 Examples nd fused alumina-zirconia grain types.

Not surprisingly, since electrofused technology has been available for 100 years, many variations of the process exist both in terms of starting compositions and processing routes. Some examples are illustrated in Figure 5.3.