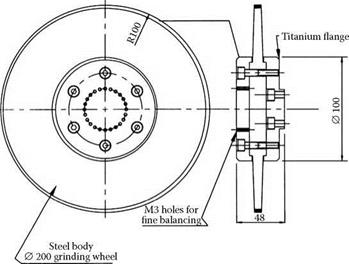

As a final note, Ramesh [2001] reported using titanium flanges as a wheel mount option in a thesis on high-speed spindle design and grinding. This design is shown in Figure 4.24.

The wheels are made with steel cores and without a center hole being held by titanium flanges clamping to shoulders on the wheel. Titanium has comparable strength to high tensile steel but has one third the density. It is, therefore, expected that the wheel core will try to expand more than the flanges at high speeds and therefore the radial clamping will increase.

|

FIGURE 4.24 Mount method for high-speed wheels using titanium flanges. (From Ramesh 2001. With permission.) |

4.7 WHEEL DESIGN AND CHATTER SUPPRESSION

Chatter is an ever-present problem in grinding. Many claims have been made that the design of the wheel, especially regarding the use of hub materials with high damping characteristics used in conjunction with superabrasive wheels, can suppress its occurrence [Broetz 2001, Tyrolit 2001]. The reality is much more complicated and requires a brief discussion of the sources of vibration and chatter in grinding.

4.7.1 The Role of Damping

The basic equation for motion of a single-degree-of-freedom system is given by

x"(t) + 2Za>nx'(t) + (on2x(t) = F(t)

where

Z = damping factor

an = natural frequency

In the absence of damping, energy is exchanged without loss during the course of motion at particular natural frequencies and the amplitude of vibration will build over time depending on the rate of input of energy. Damping absorbs energy either through internal friction of the particular material or more often in joints and seams. Prediction of the damping of a machine is not possible although damping in a particular mode of vibration may be determined empirically by use of a hammer test and measuring the decay rate. Damping is related to decay rate according to

S = (2 ttZ>/(1-Z2)1/2 = logarithmic decrement

4.7.2 Forced and Self-Excited Vibrations

The source of the energy that creates vibration can be either external leading to forced vibration or inherent in the instability of the grind process leading to self-excited vibration.