The current limit for steel-cored vitrified CBN wheels due to stresses in the abrasive layer from core expansion is considered to be 200 m/s. This will vary somewhat depending on the particular bond and layer depth. However, for speeds of 160 m/s and greater the steel is sometimes replaced with a material of comparable elastic modulus but one third the density, namely, carbon fiber reinforced plastic (CFRP) or even titanium. This reduces wheel expansion by a factor of 3. Several wheel suppliers offer high-speed wheels with CFRP hubs in their literature. However, the cores are expensive if provided with the appropriate carbon fiber (CF) reinforcement level. CFRP hubs with lower CF content are available for lower wheel speeds that offer purely weight benefits. The primary problem with mounting a carbon fiber center is that the fibers are layered mats with a high Young’s Modulus in the radial direction but a low compressive modulus axially. Either a steel flange ring is required for the bolt heads to lock against or steel inserts must be added into countersunk bolt holes.

4.6.7 Electroplated Wheels

Electroplated CBN wheels have been developed for considerably higher wheel speeds than vitrified CBN. The plated layer can withstand greater expansion of the hub. Research was reported as early as 1991 by Koenig and Ferlemann [1991] at 500 m/s using Winter wheels, while Tyrolit recently also offered a similar product design rated for 440 m/s in its literature.

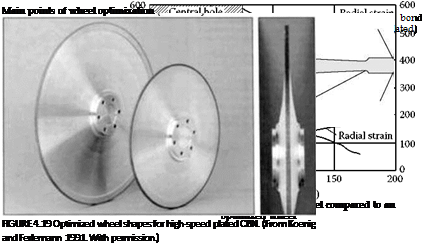

The wheel design described by Koenig and Ferlemann (Figure 4.19) has several novel features including the use of lightweight aluminum alloy for the hub material, a lack of a bore hole to further reduce radial stress, and an optimized wheel body profile based on turbine blade research to give the

minimum wheel mass for uniform strength. Although this technology has been available for 10 years, there are only a limited number of machines in actual production running over 200 m/s. The radial expansion at 500 m/s is about 160 pm! A plated CBN layer can withstand the expansion at high speed, but the expansion is rarely perfectly uniform. Even a 1% difference due to any anisotropy in the hub material will lead to regenerative chatter and performance issues well before the expected life of the wheel.