Segmental wheel research first began with conventional wheels in the 1970s as part of an effort to evaluate the effect of high speed [Yamamoto 1972, Anon 1979, Abdel-Alim, Hannam, and Hinduja 1980]. However, the labor-intensive manufacturing costs were not competitive for the economic gains in productivity possible at that time. However, the recent development of ultrahigh porosity specifications (and therefore low-density) using extruded SG abrasives has allowed the development of wheels with thick layers of conventional abrasive capable of operation at up to 180 m/s. An example is illustrated in Figure 4.9.

|

|

|

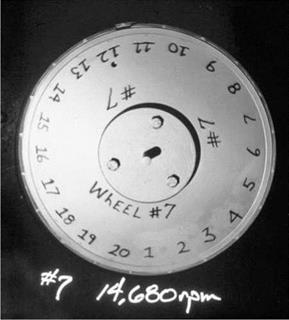

FIGURE 4.10 Solid wheel failure at 90 m/s (monolithic alox body). |

4.4.8 Safety of Segmented Wheel Designs

The last and most important benefit of segmental designs is safety. The two high-speed photographs compare the failure of a conventional wheel (Figure 4.10) with a high-speed segmental wheel (Figure 4.11). The failure in the latter can just be seen between segments 11 and 12.

|

|

|

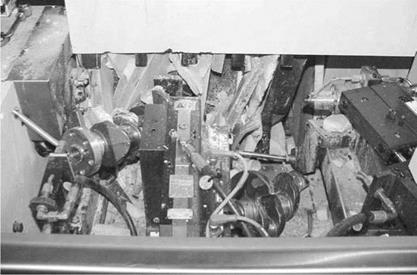

FIGURE 4.12 Wheel failure in a multiwheel cylindrical grinding operation. |

The major difference in the two failures is the energy release. The results of a failure in a large conventional wheel can be extremely destructive for the machine tool, as illustrated in the photograph (Figure 4.12) showing the aftermath of a multiwheel crankshaft journal wheel set failure. With this level of energy released, the situation is potentially very dangerous, costly, and timeconsuming even when well guarded. By comparison the energy released by a segment failure, and the level of damage accompanying it, are very small. Any failure though is still unacceptable to the wheel maker or end user.

Figure 4.13 compares the energy release in wheel failure for a quadrant of a conventional wheel compared with the energy release for a segment of a segmented wheel.