|

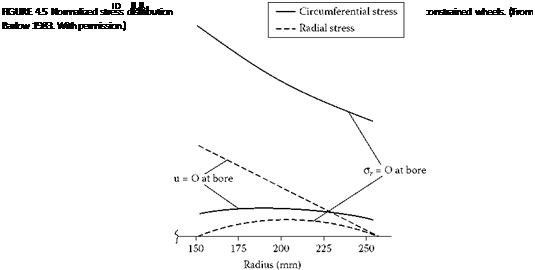

Wheel failure, in line with this analysis, occurs from cracks generated at or near the bore where the stress is highest. The failure is catastrophic with conventional wheels. Typically four or five large,

|

FIGURE 4.6 Segmented vitrified CBN wheels and molded segment cross sections. (Courtesy of Saint-Gobain Abrasives. With permission.) |

highly dangerous pieces are flung out. To increase the burst speed either the overall strength of the bond must be increased (e. g., finer grit size, lower porosity, better processing methods must be applied to eliminate large flaws), or the strength must be increased where the stress is highest. For conventional wheels this has often been achieved with a two-component vitrified structure where the inner portion is higher strength, although not necessarily suitable for grinding.

For vitrified CBN wheels higher speeds are achieved by substituting the inner section of the wheel with a higher strength material such as aluminum, carbon fiber reinforced plastic (CFRP), and especially steel.