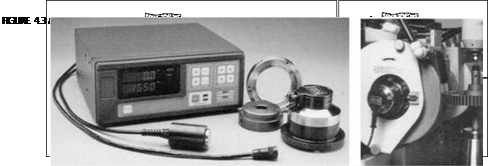

Most recently, automatic balancers have been developed for dynamic balancing in two planes for compensation of long wheels such as for through-feed centerless grinding or for complete wheel/spindle/motor assemblies.

4.3.5 Coolant Unbalance

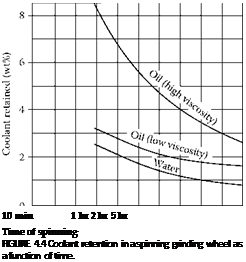

Coolant is a key factor for maintaining balance. A grinding wheel can absorb a considerable quantity of coolant (e. g., 220# WA 1A1 wheel can hold up to 16 wt%). When spun, the coolant is not released instantaneously but may take several minutes or even hours depending on its viscosity. This can be seen in Figure 4.4, which shows the rate of loss of retained coolant in a

|

Balance

reject

Balance

limit

12 in. x V2 in. WA 220# 1A1 wheel spun at 48 m/s. The primary problem arises when coolant is allowed to drip on a stationary wheel or a stationary wheel is allowed to drain vertically. This will throw the wheel into an unbalanced condition when next used. The effect is unlikely to cause actual wheel failure, although it can happen. However, coolant unbalance will generate prolonged problems of vibration and chat-ter even when constantly dressing the wheel. It is also an issue with vitrified CBN wheels at high-enough wheel speed (>60 m/s) even though the porous layer may only be a few millimeters thick.