3.5.1 Microplowing, Chipping, and Breaking

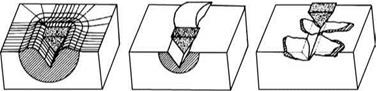

The removal process during the engagement of an abrasive cutting edge on the surface of a workpiece mainly depends on the physical properties between the active partners. A basic distinction can be made between three different mechanisms: microplowing, microchipping, and microbreaking (Figure 3.7).

In microplowing, there is a continual plastic, or elastoplastic, material deformation toward the trace border with negligible material loss. In real processes, the simultaneous impact of several abrasive particles or the repeated impact of one abrasive particle leads to material failure at the border of the traces. Ideal microchipping provokes chip formation. The chip volume equals the volume of the evolving trace. Microplowing and microchipping mainly occur during the machining of ductile materials. The relation between microplowing and microcutting basically depends on the prevailing conditions such as the matching of the active partners of the grinding process, grinding parameters, and cutting edge geometry.

Microbreaking occurs in case of crack formation and spreading. The volume of a chip removed can be several times higher than the volume of the trace. Microbreaking mostly occurs during the machining of brittle-hard materials such as glass, ceramics, and silicon.

Hence, the mechanisms of surface formation during grinding consist of these three basic processes. Which of them predominates strongly depends on the workpiece material. Therefore, material removal mechanisms will be presented in Section 3.6 for ductile materials on one hand, and for brittle-hard materials on the other.

|

Microplowing Microchipping Microbreaking FIGURE 3.7 Physical interaction between abrasive particles and the workpiece surface. (From Zum 1987. With permission.) |