3.2.1 Introduction

In the case of grinding, the cutting process is the sum of singular microscopic cutting processes, whose temporal and local superposition leads to a macroscopic material removal. As a consequence, the cause-and-effect principle of grinding can only be described on the basis of the cutting behavior of the individual abrasive grains [Sawluk 1964]. The most important parameter is the number of the currently engaged cutting edges [Kassen 1969]. An exact determination of the geometrical engagement conditions of the single cutting edges, however, is not possible for manufacturing processes like grinding or honing. Due to the stochastic distribution of the geometrically not defined cutting edges, their position and shape cannot be exactly determined.

Therefore, the position, number, and shape of the abrasive grains are analyzed statistically and related to the process kinematics and geometry to achieve a specification of the engagement conditions of the abrasive grain. Thus, grinding results can be related to events at the effective area of grinding contact for particular input values of machine and workpiece parameters and other specifications of the process. The main cutting parameters of the removal process are the theoretical chip thickness, length, and engagement angle. Knowing the overall relations between input values, cutting and chip values, as well as process output values, the behavior of the process can be cohesively described and used to improve the set-up of the machining process. This implies a wheel specification suitable for the grinding situation and the choice of parameters leading to an economical grinding process.

Different authors have described the material removal mechanisms of diverse grinding processes. Thereby, a distinction is made between topography, uncut chip thickness, grinding force, grinding energy, surface, and temperature models in relation to different basic models [Kurrein 1927, Pahlitzsch and Helmerdig 1943, Reichenbach et al. 1956, Kassen 1969, Werner 1971, Inasaki, Chen, and Jung 1989, Malyshev, Levin, and Kovalev 1990, Lierath et al. 1990, Toenshoff et al. 1992, Paulmann 1990, Marinescu et al. 2004].

3.2.2 Specification of Single Cutting Edges

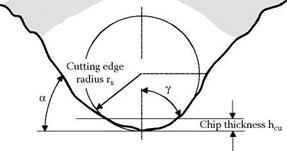

The geometry of single cutting edges may be described statistically by measurement of cutting edge profiles. The depiction of the form of a cutting edge of an abrasive grain represents the average of all measured geometries. The main characteristic of the cutting edges acting during grinding is the clearly negative rake angle (Figure 3.1).

Direction of cut ►

|

Abrasive grain

FIGURE 3.1 Average shape and analytic description of a cutting edge. (From Koenig and Klocke 1996. With permission.) |