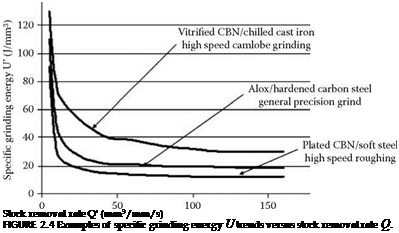

Grinding power, P, can be estimated from the specific grinding energy, ec, using the equation

P = e • Q ‘■ b

c w

|

where bw is the width of grind.

2.2.12 Tangential Grinding Force

Tangential grinding force, Ft, may then be calculated from

2.2.13 Normal Grinding Force

Normal grinding force, Fn, is related to the tangential grinding force by the coefficient of grinding, a parameter defined in a similar way to friction coefficient.

2.2.14 Coefficient of Grinding

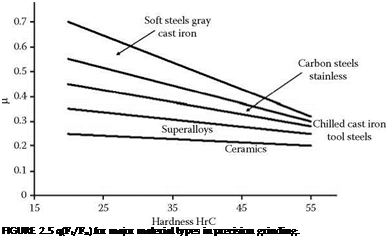

Coefficient of grinding is p, where

The value for p can vary from as little as 0.2 for low stock removal applications for grinding hard steels and ceramics to as high as 0.8 in very high stock removal applications such as peel grinding, or grinding soft steels or gray cast iron. Coolant can also have a major impact on the value as a result of the hydrodynamic pressure created by high wheel speeds. The effect is particularly noticeable with high-viscosity straight oils. Typical precision-grinding applications on steels have values of p in the range of 0.25-0.5.

|

Since tangential force can be readily calculated from power but not from normal force, knowledge of p is particularly useful to calculate required system stiffness, work holding requirements, chuck stiffness, etc. Figure 2.5 plots general values for p as a function of material classes and hardness. For most precision production grinding processes with hardened steel or cast iron it can be seen that p tends to a value of about 0.3. Note, however, that these numbers are for flat profile wheels in a straight plunge mode. If a profile is added to a wheel or the angle of approach is changed from 90°, then allowance must be made for increased normal forces and for side forces.