Specific grinding energy, ec (or u in older publications), is the energy that must be expended to remove a unit volume of workpiece material. The units are usually J/mm3 or in. lb/in.3; conversion from metric to English requires a multiplication factor of 1.45 x 105. Analysis of the energy to create chips leads to the following relationship between ec and hcu:

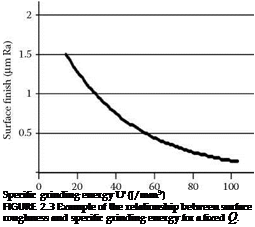

where n = 1 for precision grinding. The relationship is logical insofar as it takes more energy to make smaller chips, but is valid only so long as chip formation is the dominant source. In general terms, for precision grinding of hardened steel, the surface roughness will follow a trend rather like that shown in Figure 2.3 as a function of specific energy (see below).

Hahn [1962] and Malkin [1989] show that in many cases, especially in fine grinding or low metal removal rates, significant energy is consumed by rubbing and ploughing. Under these circumstances specific energy, ec, varies with removal rate, Q, as illustrated in Figure 2.3.

2.2.10 Specific Removal Rate

Specific removal rate, Q or Q’w, is defined as the metal removal rate of the workpiece per unit width of wheel contact, Q = ae. vw. The units are either mm3/mm/s or in.3/in./min. To convert from the former to the latter requires a rule of thumb multiplication factor of approximately 0.1 (or 0.1075 to be precise).

For very low values of Q’, rubbing and ploughing dominate, but as Q increases so does the proportion of energy consumed in chip formation. More to the point, the energy consumed by rubbing and ploughing remains constant, thereby becoming a smaller proportion of the total energy

|

consumed as stock removal rates increase. Precision grinding for the steels illustrated in Figure 2.4 gives specific energy values of 60-30 J/mm3, of which about 20 J/mm3 is associated with chip formation.

Chip formation dominates in high removal-rate precision applications such as camlobe grinding or peel grinding with vitrified CBN or rough grinding with plated CBN. Under these circumstances

is a good predictor of performance.