1.3.1 The Basic Grinding Process

|

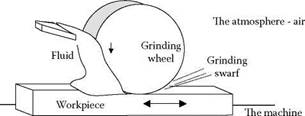

Figure 1.1 illustrates a surface-grinding operation. Six basic elements are involved: the grinding machine, the grinding wheel, the workpiece, the grinding fluid, the atmosphere, and the grinding

|

swarf. In addition, there is the need for a dressing device to prepare the grinding wheel. The grinding wheel machines the workpiece, although inevitably the workpiece wears the grinding wheel.

Grinding swarf is produced from the workpiece material and is mixed with a residue of grinding fluid and worn particles from the abrasive grains of the wheel. The swarf is not necessarily valueless but has to be disposed of or recycled.

The grinding fluid is required to lubricate the process to reduce friction and wear of the grinding wheel. It is also required to cool the process, the workpiece, and the machine to prevent thermal damage to the workpiece and improve accuracy by limiting thermal expansion of both workpiece and machine. The grinding fluid also transports swarf away from the grinding zone.

The atmosphere plays an important role in grinding most metals by reducing friction. Newly formed metal surfaces at high temperature are highly reactive leading to oxides that can help to lubricate the process. It is usual to emphasize physical aspects of grinding, but chemical and thermal aspects play an extremely important role that is easily overlooked.

The machine tool provides static and dynamic constraint on displacements between the tool and the workpiece. The machine tool stiffness is therefore vital for achievement of tolerances for geometry, size, roughness, and waviness. Vibration behavior of the machine also affects fracture and wear behavior of the abrasive grains.

To summarize, the main elements of an abrasive machining system are [Marinescu et al. 2004]:

The workpiece material, shape, hardness, speed, stiffness, thermal, and chemical properties

The abrasive tool, structure, hardness, speed, stiffness, thermal, and chemical properties, grain size, and bonding

The geometry and motions governing the engagement between the abrasive tool and the workpiece (kinematics)

The process fluid, flowrate, velocity, pressure, physical, chemical, and thermal properties

The atmospheric environment

The machine, accuracy, stiffness, temperature stability, vibrations