The first mill for making particles about 1 pm in diameter was invented by Herman Plau — son at his research institute in Hamburg in 1913 with the intention of making colloidal

|

|

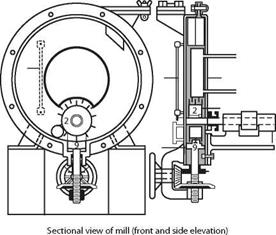

FIGURE 8.3 Plauson-Block colloid mill (Forster and Reilly 1922)

coal, although it was 1922 before it was used in industry. Within a few years, colloid mills were being used for grinding pigments for inks and paints; phosphates; feldspars for use as fertilizers without sulfuric acid treatment; and sulfur for use in agriculture. The Plauson-Block mill is shown in Figure 8.3.

The mill consisted of a water-cooled casing and front cover, an axle carrying a set of beaters, and two sets of fixed anvils through which the blades of the beaters passed with 1-3 mm clearance. The axle in a 15-L mill was driven by a 22.4-kW motor and rotated at 3,000 rpm. The regime was intensely turbulent, and particles were shattered and abraded by impact.

It is stated that three 15-litre machines in series, running at 9000 rpm can grind 1000 kg of raw phosphate or 200 kg of cellulose in an hour to such a state of division that 85% of the particles are estimated to be of the order of.001 mm dia.

(Forster and Reilly 1922)

Another high-speed mill that was first used in the 1920s to make colloids is shown in Figure 8.4. “Machines of this type consist of a smooth moving surface which passes a smooth fixed surface at a high velocity (3 km per minute or higher) and with a small clearance (50 microns)” (Travis 1929). This type of mill was effective for deflocculation and dispersion and was used in the paint industry and for the breakage of mica and clays. Flat disks as well as cones were used as the grinding elements.