Balls used in the first compartment are larger than those in the second because much larger particles must be broken. Sizing distributions vary according to clinker characteristics and whether the mill is in open or closed circuit. Some clinkers contain small, hard nodules about 10-15 mm in size that grind slowly and may enter the second compartment by flowing through the large grates in the center of the partition. They accumulate at the discharge end of the mill, and at times a few large balls are added to the second compartment in an attempt to fix the problem. Table 7.3 gives the loading and size distributions of balls for some two-compartment mills.

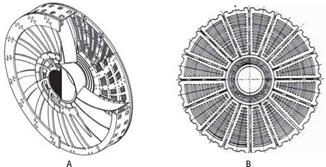

Although dry tube mills seem to be simple devices, in fact they are complex, and every aspect of their design and operation has to be considered carefully if good performance is to be achieved. For example, division heads are used for separating the grinding chambers that operate at different conditions (ball charge, ball size, linings) in the multiple — compartment ball mills. The aperture size of the diaphragm controls the top size of particles in the next chamber by restricting the passage of the grinding media and oversize material. Division heads can be classified under two major groups: (1) those used between drying and grinding chambers in mills for grinding raw materials and (2) those used between chambers in mills for grinding cement clinker (Figure 7.17).

Different designs are used for diaphragms between drying and grinding chambers and between grinding chambers. Scoops move material to the center of the division

|

TABLE 7.3 Loadings and size distributions of balls in two-compartment mills Mill: 3.65 m in diameter by 10.3 m long, 1,300-kW motor, 49-tph feed rate Raymond separator: 5.5 m in diameter

|

|

|

head, from which it passes into the next grinding chamber of the mill. Division heads may have a coarse screen in the center so that the airflow is not impeded.

Some single-compartment wet-grinding ball mills also have discharge diaphragms and are called diaphragm or grate ball mills. Most larger-diameter wet-grinding ball mills in the mining industry are overflow mills that do not require grates. Problems resulting from grates becoming plugged with worn balls and the lower wear life of grates led to a general preference for overflow mills.