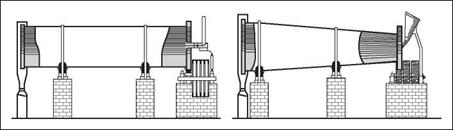

In the mid-1890s, lawyers became interested in tumbling mills. In 1891, a patent specification was lodged with the Imperial Patent Office of the German Reich (Scheibe 1993) in which priority was claimed for the use of solid metal sections rather than screens on the cylindrical part of the mill. The purpose of the invention was to eliminate the problems in operation caused by the screens. Figure 7.14 shows the cylindrical and conical mills described in the patent. Patents for tumbling mills were ignored until 1897 when very fine grinding started to become important. The Krupp Company and the Luther Company had been making tumbling mills in Germany for some years by then, so they strongly defended their case when the claim was made that they infringed on the 1891 patent. A 1-year lawsuit took place during which decisions about the validity of the patent were made, which were reversed on appeal, but eventually the lawsuit ran out of steam as the patent’s expiration date approached.

|

FIGURE 7.14 Tumbling mills described in the 1891 German patent (Scheibe 1993; reprinted by permission of Klaus Graichen) |

|

|

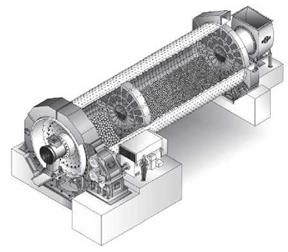

Tube mills with two and occasionally three compartments became the workhorses for grinding cement clinker and other dry materials during the 20th century and will be used extensively for dry grinding for many years. Tube mills have increased greatly in size to meet the rising demand for cement; mills are now as large as 5.5 m in diameter by 16.5 m long, and powered by 7,000-kW (10,000-hp) motors (Duda 1987).

Figure 7.16 shows a modern, high-capacity two-compartment mill. Mill capacities have increased tenfold since 1950, from 35 to 350 tph. The engineering techniques for design and construction that are now available mean that mill diameter and length can

|

|

FIGURE 7.16 Modern two-compartment tube mill (reprinted by permission of Krupp Polysius)

be increased to meet any required capacity. Two-compartment tube mills modified for intermediate classification between the compartments are finding increasing use for grinding refractory gold ores that must be roasted to enhance the efficiency of leaching. These types of tube mills are described later in this chapter. As two-compartment mills have become larger and their capacities have increased, attention has turned to the internal fittings of the mills such as the ball loading, the division head between the compartments, and the mill linings.