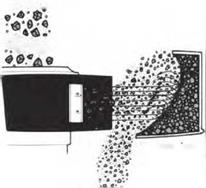

In hammer mills the impact of a fast-moving hammer on a slow-moving rock causes shattering. It can also be caused by the collision of a rock traveling at high velocity with another rock or a breaker plate. This is the concept of a vertical-shaft impact crusher.

|

FIGURE 5.19 Sectional view of the hammer mill (McGrew 1950; reprinted by permission from Primedia)

FIGURE 5.19 Sectional view of the hammer mill (McGrew 1950; reprinted by permission from Primedia)

Crushed Product

![]() A

A

A problem with the original machine was that the maximum size of feed to the rotor was too small; it was 60 mm and it needed to be 100 mm. The solution was to add the larger particles as a separate flow directly into the breaking chamber. This machine was called a dual-feed machine or a Barmac Duopactor. The Barmac crusher (see Figure 5.20) was invented in 1970 by Jim Macdonald, an engineer with the Wellington City Council in New Zealand. He took the view that two principles were involved in crushing:

■ Stones will break if you bang them together hard enough (thus saving wear on metal parts).

■ Steel will be protected from abrasive wear if covered by a layer of trapped stones (Bartley 1996).

A basic prototype proved that the idea was sound, so, with the assistance of partner Bryan Bartley, a commercially viable machine was made. By 2002, more than 3,300 Barmac crushers had been sold, the largest being a 650-kW unit for use in an iron ore mine.