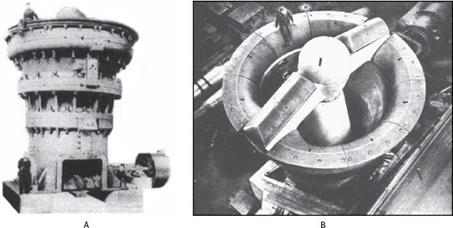

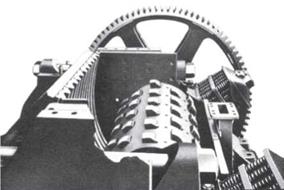

Several types of single-roll mills have been built in which the solids are broken by being nipped between the rotating roll and a fixed surface. An early single-roll machine was the sledging roll crusher, which was built by Allis-Chalmers in 1911. It was a single-roll toothed crusher that was typical of a family of similar crushers built during the 20th century. Two units (0.9 m x 1.5 m) were installed in the Fairmount, Illinois, flux limestone plant of the Casparis Stone Company, and they quickly achieved a high degree of popularity. Units of this type came to be called “Fairmount” crushers, and the line was expanded to include smaller sizes as well as a big 1.5-m x 2.1-m machine, which is shown in Figure 5.15.

The roll center is made of cast steel and the teeth are of manganese steel inserted in cored pockets in the surface of the roll center. These teeth, it will be noted, are of different heights, the higher teeth being known as the slugger teeth and the lower ones as the regular teeth. The tip velocity of the slugger teeth in the Fairmount crusher is from 400-450ft per minute. The working faces of the teeth are radial in profile which means that the faces are normal to the line of action when a rock is contacted in any part of the crushing chamber. …On the soft and medium grades of stone, to which the single roll crusher is particularly well adapted, the machine will turn out a product carrying less fines than will either the jaw or gyratory types. …most of the crushing is done by clean sharp sledging blows against the individual pieces. (McGrew 1950)

|

|

|

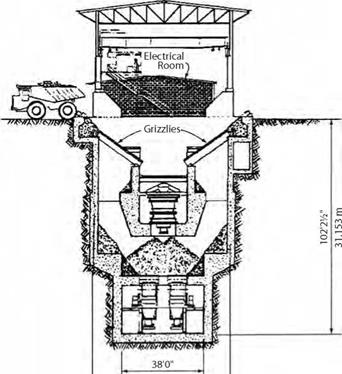

FIGURE 5.14 Sketch of the primary crusher installation at Bougainville Copper Limited (McQuiston and Shoemaker 1978)

|

|

FIGURE 5.15 Fairmount single-roll crusher (McGrew 1950; reprinted by permission from Primedia)

Similar types of single-roll crushers were made by many companies during the 20th century. Because of their low fines production, these crushers were suitable for coal breakage. Coal, which is brittle and breaks easily, had been broken manually until about 100 years ago, when engineers began to adapt hammer mills and roll crushers for crushing coal, and low — and high-speed crushers were used to crush run-of-mine coal to about 150 mm.