Mortars and pestles and saddlestone mills had several problems: the exhausting motions required of the operator, the batch nature of the processes, and the unnecessary rebreaking of particles that were already small enough. The invention of the rotary quern, probably around 600 bc (estimates of the date of its appearance vary by several hundred years), solved these problems. Querns, which used shearing and compression forces, had a fixed lower stone and an upper stone that rotated on a pin, so that the moving and fixed surfaces were just clear of each other. The hole in the lower stone of the early quern contained a spigot on which the upper stone spun, just clear of the lower stone.

Originally the upper stone was probably always lifted off when fresh grain was added. Later however the upper stone had a hole in the centre while the lower had a projection which passed through this hole. Between this pivot and the hole enough space remained for adding grain when necessary. In order to spread the grains entering at the central hole over the whole space between the two millstones the latter had small grooves running out radially between which further grooves were inserted inclined at acute angles to them. (Neuberger 1930)

Compared with saddlestone mills and mortars and pestles, rotary querns had several advantages. They could be operated manually in a rotary motion by a crank, which is a vertical shaft attached to a horizontal spoke. The crank, which was an important engineering advance itself, enabled the stone to be turned more easily:

Crank motion first appeared in querns among people who still ground their grain at home. The quern maker drilled a vertical hole near the edge of the upper stone and stuck a peg in the hole. The operator could then spin the upper stone round and round more easily than she could with radial spokes where she had to change her grip with every revolution. In fact she could turn out about a bushel of flour every day-twelve times as much as before. (de Camp 1970)

Figure 3.9 shows how querns evolved. At first they were small hand-operated units in family dwellings that made enough flour for a single family. As they came to be used by several families and then by whole villages and towns, ever-larger machines with higher production rates were built. The mills at Pompeii, shown in Figure 3.10, were 2 m high, and these mills, and the ovens that were built beside them, were the core of a large

commercial milling and baking complex. In addition to the higher production rates, the quality of the flour was higher (Ward-Perkins and Claridge 1980).

Hellenistic and Roman mills finally took the form of the hour-glass mill. While the lower stone was conical the upper was cylindrical. This cylindrical stone was hollowed out to fit the cone below and had a similar cone-shaped hollow above, into which the grain was fed. An adjustable wooden pivot made it possible to regulate the clearance between the stones and thus to grind the grain to the desired fineness. The hour-glass mills at Pompeii were huge affairs 2 m (6.5 ft) high weighing hundreds of pounds. Capstan spokes projecting horizontally made it possible to turn the upper stone. (de Camp 1970)

In the mills at Pompeii, men turned the upper millstone in the hourglass type of mill by pushing on spokes that were inserted in slots. Boring holes in tough stones was not easy with the tools of the day. Beedell (1975) suggested that people bored holes by spinning a pointed hardwood stick with a bowstring and pouring wet sand around it as an abrasive. The pilot hole could then be expanded.

|

|

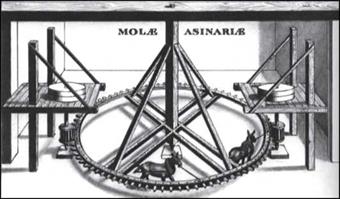

FIGURE 3.11 Querns driven by animals (de Camp 1961)

|

FIGURE 3.12 Evolution of harnesses for making use of the power of animals: (a) neck yoke— pulling from shoulders (b) dorsal yoke—pulling from chest (c) traction harness—pulling from lower part of neck (d) shoulder-collar harness (e) breast-collar harness (Clutton-Brook 1952; reprinted by permission from British Museum) |

In time, animals came to be used as a source of power. Although animals cannot drive a machine that has a reciprocating motion, they can be harnessed to a shaft and drive a rotating stone by walking in a circle. Figure 3.11 shows one method of using animals to drive a quern. By 200 bc mules and donkeys were replacing men for this task, although the use of animals was relatively uncommon because slaves continued to be the cheapest and most flexible source of energy.

A difficulty with using animals was in designing a harness that would allow the animal to effectively transmit its power to the machine. The first harnesses were placed around the neck of the horse, but as loads increased, these harnesses tended to tighten and even strangle the animal. Gradually the design changed to relieve the stress on the neck, eventually reaching the point at which full power could be delivered through the modern shoulder-collar and breast-collar harnesses. Figure 3.12 shows the evolution of the harness (Clutton-Brook 1952). Although the use of animals to power grinding querns had limitations, it was an important development, because it was humankind’s first extension of the use of animal power since animals were harnessed to plows and carts 3,000 years earlier.

The skill of the craftsman in stone working was a crucial factor in the evolution of the quern. These skills can be admired in the magnificent stonework in the pyramids and monuments in Central America and in the eastern Mediterranean, but they were also necessary for building the great querns in cities such as Pompeii. The high production

rates of these querns led to the commercial baking industry. By the latter part of the 4th century, there were 254 bakeries in Rome (Mosse 1969).

Querns were used for grinding grains until late in the 19th century, when rolls were found to be more efficient for producing high-quality flour. Rolls now dominate grinding for the production of flour, but water-driven querns can still be found in many communities. Two types of crushers that are widely used today had their origins in querns: (1) disk crushers, which are mainly used for corn, and still feature the grooves from earlier times; and (2) cone crushers, which are used for ores and aggregates.

The quern was an outstanding invention. It greatly increased the output of workers and “constituted the earliest complete grinding machine: the first in which the parts were combined into a perfect mechanism” (Bennett and Elton 1898-1904). It made the grinding of wheat so much easier that it became essential in every household. “The two ever present sounds of households were the clack of the loom and the grate of the hand mill” (de Camp 1970).

Limitations of Querns Querns were heavy and expensive, because they were made of large, tough stones weighing up to hundreds of kilograms each. With care they would last for many years, even generations. Suitable stones could be found in a limited number of locations, and a significant trade developed in stones for querns and for other grinding devices such as hopper-rubbers. Considerable skill was needed to set the quern stones so the machines would break the particles efficiently with minimum wear. If the gap was too large, the corn was not ground properly; if too small, the corn was burnt; and if the stones were set to touch, they wore out quickly.

And there was always the problem of power. Grinding was carried out under duress by prisoners and slaves, only occasionally by free men or women with no other means of livelihood. Grinders generally had a short life expectancy because of the harshness of the task, the grim living conditions, and the unending work in a dusty atmosphere. New slaves were always needed to grind raw materials for flour and metals. When the Roman Empire was expanding through conquest, this was less of a problem because plenty of captives could be forced into slavery. It has been estimated that by 28 BC there were 40 million free citizens and 20 million slaves in Italy and as many more again in other countries of the Roman Empire (Hopkins 1978). A population of this size required considerable food to keep it functioning, and many slaves were needed to grind the wheat to produce the bread.

But when the Roman Empire expanded to include the principal nations of Europe, Africa, and West Asia, and the people from those areas had been enslaved, the sources for slaves dwindled and there were no more countries to be conquered. Other methods had to be devised to supply an adequate source of energy for grinding, which led to the harnessing of water as an alternative energy source.