The mortar proper rested on a stand whose height was such that its upper rim reached about to the knee of the worker, or else it and the stand were made of one piece. The pestle was made of wood about 30 to 39 inches long and narrowed down at the middle so that it could be conveniently grasped. (Neuberger 1930)

By 6000 bc, mortars and pestles were being used for size reduction. Rocks such as basalt or hard limestone were suitable materials for grinding grains, and very hard volcanic stones such as trachyte or sanidine feldspar were used for breaking ores. Impact and compression were the breakage mechanisms. Wear on stone mortars and pestles was always a problem, particularly with ores, and eventually the pestles were clad with or made entirely of iron. This reduced wear and allowed for heavier impacts that made the particles shatter faster.

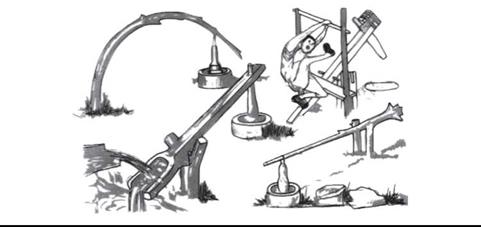

The mortar and pestle is probably the only piece of equipment that has not changed in more than 10,000 years (see Figure 3.5). It is still an essential item in many laboratories and kitchens and is used to prepare food in developing countries. Over its long history, many methods have been used to operate the mortar and pestle to make the required effort as easy as possible. Figure 3.6 shows some methods of working mortars and pestles (Kuprits 1967).

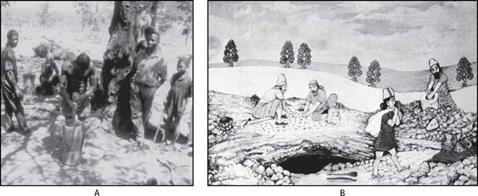

Figure 3.7a shows an operator grinding gold ore in a mortar and pestle in 1999, a scene that differs little from the one depicted on a Turkish postcard (Figure 3.7b), which shows how ore was ground in several stages for metal extraction hundreds of years ago.

She spread some handfuls of grain upon an oblong slab of stone, slightly hollowed on its upper surface, and proceeded to crush them with a smaller stone. .for an hour or more she laboured so, with arms shoulders and loins, in fact with her whole body till the operation was complete….

The “saddle” corn stone stands pre-eminent among the milling appliances of the world. It derives its name from a resemblance its concave upper surface bears to the seat of a saddle. (Bennett and Elton 1898-1904)

|

|

|

|

|

Saddlestone mills seem to have first appeared in Chaldea (part of present-day Iraq), because “…no trace appears of their existing in any other country prior to their flourishing in Chaldea” (Bennett and Elton 1898-1904). These mills consisted of small rocks with smooth faces that were rubbed in a reciprocating motion on larger fixed rock slabs, either back and forth or at an angle when attached by one end to an upright. The upper stone did not roll. The fixed slabs were slightly hollowed and usually sloped slightly downward, away from the workers. The reciprocating motion was exhausting to maintain and wasteful of energy because particles that were already small enough were rebroken. Saddlestone mills, however, were better than mortars and pestles for producing very fine particles. Abrasion was the important breakage mechanism and was more effective than impact for producing very fine particles; the stones were always in contact, meaning that the particles were being worked on all the time.

With a saddlestone mill, one person could grind enough wheat to make bread for about eight people (de Camp 1970). This meant that for more than 2,000 years at least one-eighth of the world’s population carried out the backbreaking work of grinding grain by hand. More labor was needed for grinding minerals because they were much harder. The lives of the grinders in households was hard enough, but the lives of slaves and prisoners who were required to grind grain to supply large organizations such as the palace and the army must have been short and appalling.

Good gods, what a sort of poor slaves were there; some had their skin bruised all over black and blue, some had their backs striped with lashes and were but covered rather than clothed with torn rags, some had their members hidden by a narrow cloth, all wore such ragged clouts that you might perceive through them all their naked bodies, some were marked and burned in the forehead with hot irons, some had their hair half clipped, some had shackles on their legs, ugly and ill favoured, some could scarce see, their eyes and faces so black and dim with smoke, their eyelids all cankered with the darkness of that reeking place, half blind and sprinkled black and white with dirty flour marks like boxers who fight together befouled with sand. (de Camp 1970)

The Book of Judges (16:21; Good News Bible 1976) left no doubt that grinding was a severe punishment. In the story of Samson, the leader of the Hebrews was lulled to sleep by Delilah so that she could crop his hair after learning that his long hair was the source of his strength. In his weakened condition he was made a prisoner by the Philistines, his eyes were gouged out, and he was taken to Gaza bound with fetters of bronze and “.set to grinding corn in the prison.” Little wonder that when his hair grew and his strength returned, he wreaked great vengeance on the Philistines by grasping two columns of the temple and fracturing them, killing many who had gathered to make sport of him.

Medieval painters used saddlestone mills to produce pigments, and Cennini described the technique (Research Association of the British Paint, Colour and Varnish Manufacturers 1953):

To grind properly, procure a slab of porphyry which is strong and firm. …Take another stone, also of porphyry, smooth on one side, and raised on the other, in the shape of a porringer and half the height of one, of such a form that the hand may hold and guide it at pleasure. Then take some of the colour and put it on the slab, and with that stone which you hold in your hand break the pigment into small pieces. Put some clean water either from a river, a fountain, or a well, to the colour and grind it well for half an hour, or an hour, or as long as you please: but know that if you were to grind it for a year, so much the better would be the colour.

|

FIGURE 3.8 Saddlestone mills ([a] Bennett and Elton 1898-1904 [b] Perrogon 1994) |

Saddlestone mills (shown in Figure 3.8) were the main fine-grinding devices for more than 1,500 years. Their importance diminished after the quern was invented, but they were still being employed in a few places in the 20th century.