In research, grinding force components are primarily measured by means of piezoelectric sensors [BAUS03, KARP01]. However, an exact force measurement with piezo-electric force sensors is expensive and is thus used industrially only as an exception. For this reason, force sensor plates or rings are being used increasingly in industrial praxis which are equipped with several single-component quartzes situated in the force side flow. Here the calculation of the machining force components is very difficult, so that mostly only the sum of all force components is

measured. Thus a reliable recognition of wear is usually not possible, or only for very high wear values. A widespread use of force sensors in grinding machines is also hampered by the temperature drift of the sensors, which still cannot be compensated. A further factor in evaluating force sensors is the usually very high construction effort in the subsequent installation into an already existent machine-tool [LECH89, N. N.11, WECK95].

|

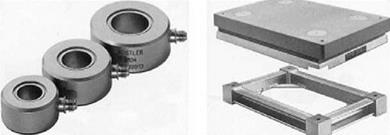

force sensors force plate

Fig. 10-3. Force sensing equipment for process detection of the Kistler company. |

A further possibility of recording machining forces indirectly is offered by force measurement dowels and extension detectors, available in the most varied designs. For example, extension can be transferred to a shear force piezo element or converted to a change in resistance with the help of a wire strain gauge (WSG). A general disadvantage of extension sensors however is that their use requires a time-consuming analysis of the respective machine in order to determine a favourable measurement location. Moreover, they have a low level of sensitivity, which mostly hinders their use in grinding machines, since here a first contact control and collision monitoring is necessary as well as an analysis of the service life end.