The spectrum of tasks the polishing fluid must fulfil comprises supporting possible chemical reactions, regulating heat, reducing the adhesion of the active partners involved in the process, and finally the distribution and transport of the abrasive. Chemical-mechanical polishing processes are strongly dependent of the pH value of the polishing fluid. When polishing copper, for example, the removal rate can be varied considerably with changes to the pH value. The highest rate is achieved in highly acidic solutions [STEI97]. According to the desired process, by using appropriate additives to the water, which forms the basis of many polishing fluids, the fluid can be made more acidic (pH < 7) or more basic (pH > 7).

A further responsibility of polishing is to be seen in adhesion reduction. Given dry friction between two bodies, large welded areas form on the contact surfaces. When these connections are broken, large patches of roughness are left behind on the polished surface.

|

|

Finally, the polishing fluid guarantees the transport and distribution of the abrasive [KLEM50]. In this context, it should be noted that the fluid and the abrasive must be closely coordinated in order to avoid undesirable appearances of settling, which alters the removal behaviour of the slurry.

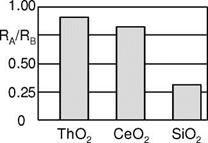

Fig. 8-22. The influence of annealing temperature and atomic structure on the ease of polishing of abrasives for glass polishing [KALL83]