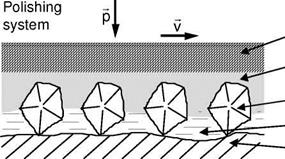

In polishing, as in lapping, the surface of the workpiece to be processed and the tool surface slide on each other. A polishing slurry is inserted between them which is composed of an abrasive and a generally water-based fluid. The active system is illustrated in Fig. 8-16. As opposed to lapping, however, much smaller abrasive particles are generally used in polishing. This clearly limits the abrasive effect. For this reason, the physical and chemical interactions taking place between the active partners in polishing are imparted an increasing importance.

Visco-elastic abrasive carrier

Abrasive Polishing fluid Workpiece

possible chemical reactions between

— polishing fluid and workpiece surface

— polishing grain and workpiece surface

Fig. 8-16. The active system in polishing and the interactions occurring between the system components

Removal Mechanisms

Originally, polishing was developed for the processing of optical elements. Because of the importance of polishing technology for the progress of other sciences, a growing number of scientists have become interested over the course of time in the removal mechanisms of polishing.

Basically, the following polishing hypotheses are discussed (Fig. 8-17):

• the abrasive removal hypothesis,

• the yield hypothesis,

•

|

|

|

![]()

![]()

|

|

the chemical hypothesis.

Fig. 8-17. Hypotheses regarding the mechanism of polishing

Also, another hypothesis under discussion in reference to glass polishing is the friction wear hypothesis, largely indebted to research by Kaller. This hypothesis states that material removal in glass polishing is the result of a combination of the dissolution of the glass surface in water and the subsequent adsorption of the glass elements on the polishing grains. According to this theory, the adsorption behaviour of the polishing grains is decisive in determining the material removal. Since the dissolved elements primarily adhere to the energetically active faults in the crystal lattice of the polishing grains, abrasives with many faults in the crystal lattice demonstrate a higher material removal than those with few faults.