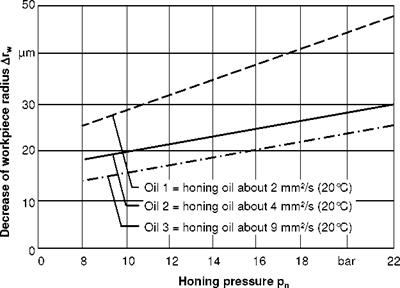

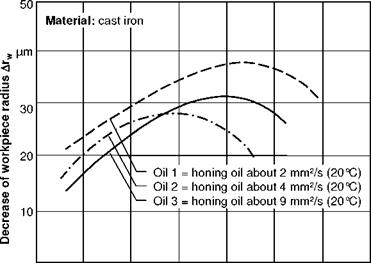

Especially for long-chipping workpiece materials, it is important that the cutting removal from the contact zone is ensured by honing oil. The lubricating effect is improved by increasing the viscosity of the honing oil. Fig. 7-30 and Fig. 7-31 show that lower viscous honing oils facilitate a greater material removal than higher viscous honing oils.

|

Fig. 7-30. The influence of honing oil viscosity on the removal rate for cast iron as a function of honing pressure [HAAS71] |

When using higher viscous oils, an oil film builds up more quickly between the workpiece and the honing stone. It has been shown that lower viscous oils require higher material removal speeds than higher viscous oils.

Fig. 7-32 assigns honing oils to different workpiece materials. On the basis of cast iron as workpiece material, two lines of development emerge. The long — chipping and tough workpiece materials are listed downwards, ending with aus-

tentic steels. The short-chipping workpiece materials are listed upwards, ending with hardened steels with 62 HRC [HAAS71].

|

0 20 40 60 80 100 m/min 140 Feed rate vft Fig. 7-31. The influence of honing oil viscosity on radial material removal [HAAS71] |