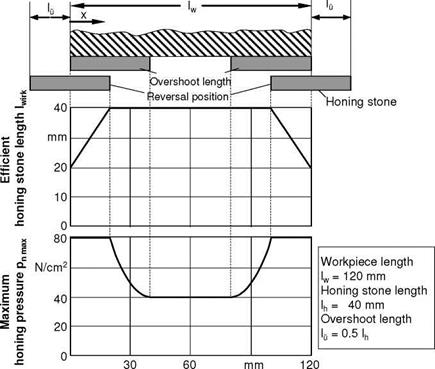

Stroke length lH has a considerable influence on shape accuracy in longitudinal stroke honing. More than in roundness errors, lH plays a decisive role in cylindric — ity errors. The larger the stroke length, the more the hole is widened at the ends. Fig. 7-15 provides a schematic illustration of the contour of a hole honed with a varying stroke length lH/overshoot length lo.

The cause for the varied formation of the hole shape lies in the following overshoot-length-dependent values:

• the efficient honing stone length and

• the honing pressure at the hole ends (Fig. 7-16).

If, for example, the overshoot length lo = 0, i. e. the axial movement reverses as soon as the end of the honing stone reaches the edge of the hole, the following conditions exist: Given that the honing stone abuts completely, the local honing pressure remains constant in the entire hole and consequently at the edge of the hole. The efficient honing stone length leff, i. e. the part of lH per stroke in which a point on the hole wall is in contact with the honing stone, is 0 at the edge of the hole and increases linearly in the axial direction up to 100 % at the honing stone end facing inwards to the inside of the hole. As a necessary consequence of the engagement of fewer and fewer grains as one proceeds towards the end of the hole given constant honing pressure, less material is removed at the ends. The hole thus tapers at entry and exit.

shortly before achieving the final dimensions in order to obtain the desired cross hatch angle a in the last overshoots at the base of the hole, as well.

|

Coordinate x of workpiece length Fig. 7-16. Efficient honing stone length and contact pressure vs. workpiece length |