A variation of the contact pressure pn does not always have an obvious influence on the process parameters and the work result. The tool’s specifications and associated wear characteristics often constitute parameters for influencing pn. In practice, however, effects arising from the contact pressure can be cited for the majority of honing processes.

Whereas in grinding the pressure/force between the tool and the workpiece depends as a process parameter on the process variables, it itself qualifies as a process variable in honing with frictional feed mechanics. In spite of the different causalities involved, the influences of force/contact pressure pn are comparable to a great extent. With an increasing contact pressure pn, the cutting edges penetrate more deeply into the workpiece surface until an equilibrium is reached between contact pressure and reaction pressure through the deepening and the broadening of the impressions and an increase in the active cutting edge number. The larger number and penetration depth of the active cutting edges increase the number and the cross-section of the chips. An increase in contact pressure under otherwise constant process variables thus results in an increased material removal per overrun (Fig. 7-8).

The same is true for the wear of honing stones. An increasing strain on the tool caused by increased cutting force leads to the breakaway of the grains from the bond and thus to greater wear of the honing stone.

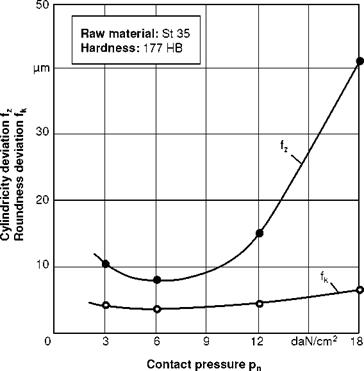

Under increased contact pressure pn, the surface quality of the workpiece is worsened. Fig. 7-8 shows the expected surface roughness for given stock removal volume. Corresponding to the greater chip cross-sections, the cutting force shows an increase with the contact pressure pn (Fig. 7-9). The influence of the contact pressure pn on the development of cylindricity and roundness errors is seen in Fig.

7- 10.

Whereas roundness errors are only minimally influenced by the contact pressure, cylindricity worsens considerably under high contact pressure. Such cylindrical form errors primarily consist in a widening at the upper edge of the hole. The widening is generated by the tool’s tilt angle, which is increased under high contact pressure and resultant high axial force.

|

Fig. 7-8. Material removal, surface roughness and honing stone wear with increasing contact pressure [TOEN70]

|

Fig. 7-10. Shape errors with increasing contact pressure [TOEN70] |

The edge force FO is constantly larger than the edge force FU (downward stroke of the tool). Higher local contact pressures and material removal rates arise towards the upper edge of the hole as a result. These considerations only apply to longitudinal stroke honing with the typical tool/workpiece arrangement as illustrated in Fig. 7-11. They do not apply to other honing processes, especially short — stroke honing.