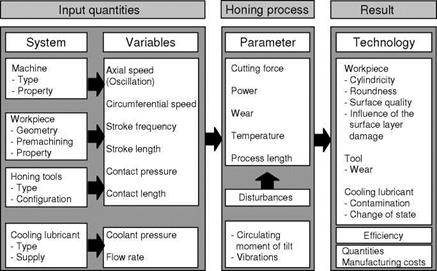

The input variables of the honing process can be divided into system quantities and variables (Fig. 7-7).

|

Fig. 7-7. Process variables and result of the honing process |

The following system quantities represent most frequently fixed process variables:

• the machine, with its performance data, material rigidity and dynamic behaviour,

• the workpiece, with its properties, geometry and state as determined by design requirements, conditions imposed by the workpiece material, and the type and quality of pre-machining,

• the honing tool, with its geometry, precision and honing stone design and

• the cooling lubricant system, with its type, viscosity and concentration of the cooling lubricant and arrangement of supply nozzles.

The variables determine the possible systems mechanics and kinematics for the process. The kinematics results from the superposition of two movements:

• axial movement, comprising the axial movement of both the tool and the workpiece and

• rotation of the workpiece/tool in the machining of cylindrical surfaces or transverse movement in the machining of level surfaces.

If the kinematics is given, the mechanics of the process is determined by the following variables:

• the contact pressure between the tool and the workpiece and

• the pressure and quantity of the cooling lubricant.

The process variables determine in their totality the process parameters and the work result. In the following, the influence of the most important variables on the work result will be discussed in more detail.